How about the quality of the diamond wire loop of the Ensolltools? What is the advantage of diamond loop wire?

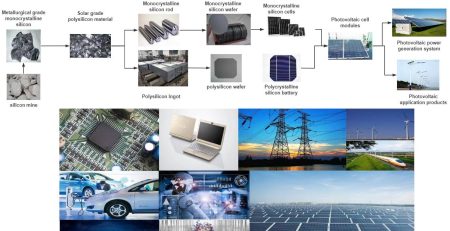

Diamond wire line is widely used in cutting tools of high hard wear-resistant materials such as photovoltaic silicon materials, graphite, synthetic ceramics and jade.

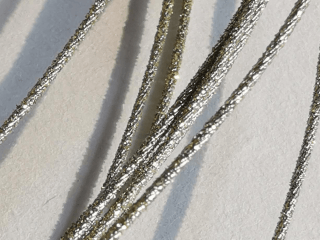

The busbar material is made of high-performance stainless steel wire, which has the advantages of strength and toughness, high tensile strength, corrosion resistance, etc., and can be customized according to customer requirements.

Zhengzhou Ensoll Tools Technology Co., Ltd. is engaged in R & D, production and sales of loop diamond wire saw. With independent intellectual property rights and a number of patented technologies, it is also second to none in the international diamond wire saw products. The company adheres to the business philosophy of technology first and service first, and helps our customers solve many problems in the cutting industry of hard and brittle materials such as tires, photovoltaic silicon, sapphire, jade, ceramics, marble and so on. In the field of diamond wire cutting, we have won the recognition and trust of customers. All industries are welcome to consult and cooperate.

At present, the commonly used diamond loop wire diameter is 0.5mm, there are other wire diameter of the ring wire, according to the characteristics of the ring wire itself, can not be thicker than the long line, you can imagine in a limited length, the smaller the diameter, the shorter the life. The key is to work hard on the process, improve the tensile strength of the loop and increase the working life per unit length. Through continuous innovation, diamond loop wire cutting has been highly recognized by the market.

In order to quickly and accurately define the needs of customers, the company will tailor the cutting wire suitable for customers according to the material, density, hardness, brittleness, chemical stability, and other indicators of the material to be cut by customers, as well as the shape structure of the section, the cutting efficiency required by customers and the cross-section quality expected by customers.