A Comprehensive Guide to Graphite Cutting

Introduction:

Graphite, known for its unique properties, has become increasingly popular in various industries. However, achieving precise cuts on this material requires the right cutting methods and tools. In this guide, we will explore the characteristics of graphite, traditional cutting methods, innovative cutting techniques, products that can be cut using diamond wire saws, and how to contact us for further assistance.

Characteristics of Graphite:

Characteristics of Graphite:

Graphite is a form of carbon that possesses excellent thermal conductivity, lubricity, and electrical conductivity. It is widely used in industries such as aerospace, automotive, electronics, and metallurgy due to its heat resistance, chemical stability, and low friction properties.

Traditional Graphite Cutting Methods:

Traditional Graphite Cutting Methods:

1.Sawing:

Sawing is one of the commonly used methods for cutting graphite. It involves the use of a conventional saw blade or a diamond-coated saw blade. The blade is moved back and forth across the workpiece to cut through the graphite material. However, this method has some limitations. The saw blade tends to generate heat during the cutting process, which can cause the graphite to expand and result in rough edges. Additionally, the cutting speed may be slower, and the precision may be compromised.

2.Milling:

Milling is another traditional method used for shaping and cutting graphite. It involves the use of cutting tools, such as end mills or ball mills, to remove material from the workpiece. The cutting tool rotates while moving along multiple axes, allowing for precise shaping and cutting. However, milling graphite can be time-consuming and result in excessive material wastage. It also requires the use of coolant to dissipate heat generated during the cutting process.

3.Grinding:

Grinding is a method commonly used for finishing and refining the surface of graphite components. It involves the use of abrasive wheels or belts to remove small amounts of material and achieve the desired surface finish. Grinding can be performed manually or with the help of automated grinding machines. However, it is not typically used for primary cutting or shaping of graphite, as it is more suitable for precision surface finishing.

4.Wire EDM (Electrical Discharge Machining):

Wire EDM is a non-traditional cutting method that uses a thin, electrically charged wire to erode the graphite material. The wire is fed through the workpiece, and controlled electrical discharges occur between the wire and the graphite, resulting in material removal. Wire EDM offers high precision and can create complex shapes with tight tolerances. However, it may not be suita

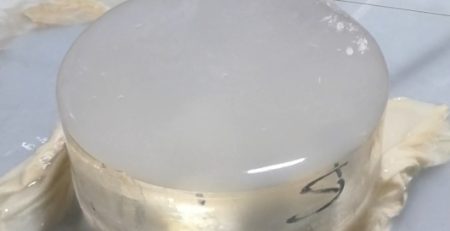

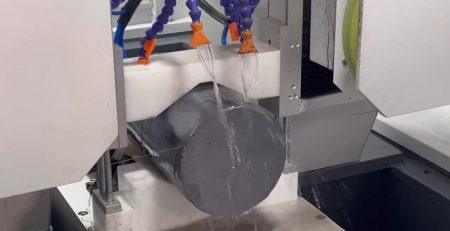

New Cutting Techniques

In recent years, the use of diamond wire saws, also known as endless diamond wire saws, has gained significant attention as an innovative cutting technique for graphite. This method utilizes a continuous loop of diamond-coated wire to achieve precise and efficient cuts on graphite materials. Let’s delve deeper into the advantages and features of diamond wire saw cutting:

1.Reduced Material Wastage:

Diamond wire saw cutting minimizes material wastage compared to traditional cutting methods. The thin diamond-coated wire allows for narrow kerf widths, resulting in less material loss during the cutting process. This is particularly beneficial when working with expensive or limited graphite materials, as it helps optimize material usage and reduce costs.

2.Enhanced Cutting Speed:

Diamond wire saws offer faster cutting speeds compared to traditional cutting methods. The continuous movement of the wire and the sharp diamond particles coating its surface enable efficient cutting through graphite materials. This increased cutting speed translates to improved productivity and shorter project completion times.

3.Improved Surface Finish:

Diamond wire saw cutting provides a superior surface finish on graphite materials. The diamond particles on the wire’s surface create clean and precise cuts, minimizing the need for additional finishing processes. This is especially crucial when working with graphite components that require a high level of surface quality, such as those used in aerospace or electronics applications.

4.Versatility:

Diamond wire saws are versatile tools that can be used for a wide range of graphite cutting applications. Whether it’s cutting graphite blocks, sheets, electrodes, or molds, diamond wire saws can handle various shapes and thicknesses. This versatility makes them suitable for industries such as manufacturing, metallurgy, and research and development.

5.Precision and Accuracy:

Diamond wire saw cutting offers exceptional precision and accuracy, ensuring that the desired dimensions and tolerances are achieved. The continuous loop of the wire allows for smooth and controlled cutting, resulting in clean edges and minimal material deformation. This level of precision is essential for graphite components that require tight tolerances or intricate shapes.

Contact Us:

For further assistance or inquiries regarding graphite cutting solutions, please feel free to contact us. Our team of experts can provide tailored advice, recommend suitable diamond wire saws, and guide you through the entire cutting process to ensure optimal results.

Conclusion:

Achieving precise cuts on graphite requires the right cutting methods and tools. Traditional methods can be time-consuming and may result in rough edges. However, with innovative techniques like diamond wire saw cutting, you can achieve efficient, precise, and high-quality cuts on various graphite-based products. Contact us for a comprehensive range of graphite cutting solutions tailored to your specific needs.