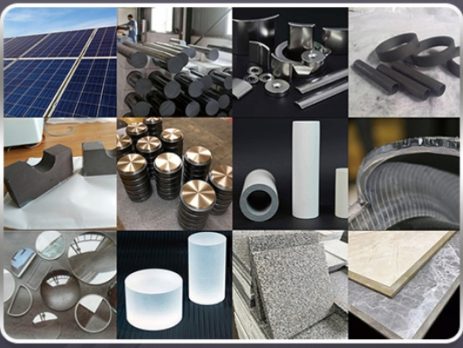

Advantages of Diamond Looped Wire Saw Cutting in the Processing of Magnetic Materials

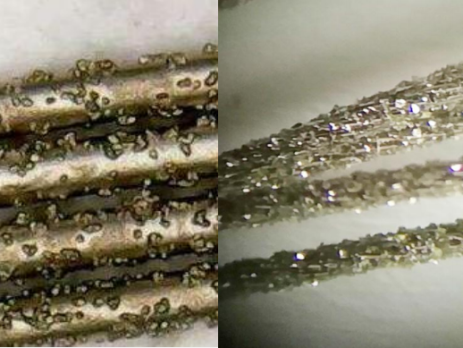

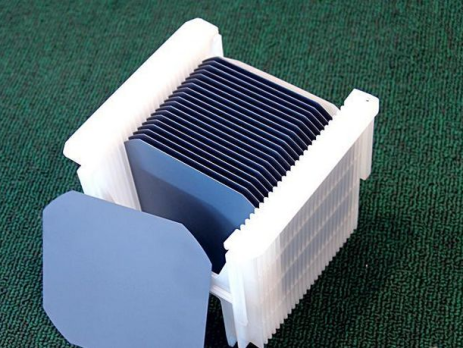

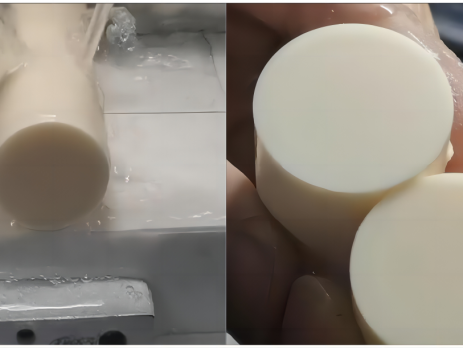

Diamond looped wire cutting possesses several significant advantages in the field of processing magnetic materials, making it an ideal cutting tool for handling magnetic materials. Here are the advantages of diamond looped wire saw cutting in the processing of magnetic materials: Hardness and Wear Resistance: Diamond is one of the hardest substances in nature, offering excellent hardness and wear resistance to diamond wire cutting tools. When cutting magnetic materials, diamond wire saw cutting can maintain the sharpness of the tool effectively, resisting...