Diamantdrahtschneiden von farbigen Kristallen: Ein umfassender Leitfaden

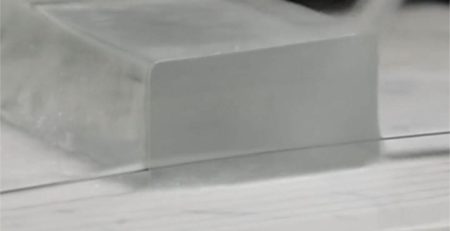

Schneiden von Diamantdrahtschlaufen has revolutionized the cutting process for colored crystals, bietet zahlreiche Vorteile gegenüber herkömmlichen Methoden. This article aims to explore the unique benefits of using diamond wire loop cutting technology specifically for colored crystals. From minimizing material loss to achieving precise and accurate cuts, diamond wire loop cutting has become an indispensable tool in the world of crystal fabrication.

Types of colored crystals:

1. Saphir

1. Saphir

Blue Sapphire: The classic blue sapphire, known for its deep and velvety hue.

Fancy Sapphires: These sapphires showcase a range of colors outside the traditional blue, including pink, yellow, and green.

Padparadscha Sapphire: A rare and prized variety with a delicate pink-orange hue, reminiscent of a tropical sunset.

2. Emerald

Colombian Emerald: Known for its intense green color and exceptional clarity, Colombian emeralds are highly sought after.

Zambian Emerald: These emeralds often exhibit a slightly bluish-green hue and are valued for their transparency.

Brazilian Emerald: Brazilian emeralds are known for their deep green color and natural inclusions, which give them a unique character.

3.Ruby

Burmese Ruby: Revered for its pigeon blood red color, Burmese rubies are considered the most valuable.

Thai Ruby: These rubies are known for their vibrant red color and can sometimes have a slight violet undertone.

African Ruby: African rubies exhibit a range of shades, from dark red to lighter pinkish-red hues.

In addition to the gemstones mentioned above, there are many other varieties that can be cut using diamond wire loop cutting technology, achieving minimal loss and precise cutting results.

Advantages of diamond wire loop colored crystal:

1.Precision and Efficiency

Superior Precision: Diamond wire loop cutting allows for precise and intricate cuts, ensuring the desired shape and size of the colored crystal.

Enhanced Efficiency: The use of diamond wire loop cutting technology enables faster cutting speeds, reducing production time and increasing productivity.

2. Minimaler Materialverlust

Reduced Wastage: Diamond wire loop cutting minimizes material loss during the cutting process, maximizing the yield of valuable colored crystals.

Cost-effectiveness: By minimizing wastage, diamond wire loop cutting helps optimize the use of raw materials, reducing overall production costs.

3.Vielseitigkeit

Adaptability to Various Crystal Types: Diamond wire loop cutting technology can be applied to a wide range of colored crystals, including sapphires, emeralds, rubies, and amethysts, among others.

Customization Options: The flexibility of diamond wire loop cutting allows for the creation of custom shapes and designs, catering to individual customer preferences.

4.Improved Surface Finish Smooth and Polished Results

Diamond wire loop cutting produces clean and smooth cuts, minimizing the need for additional polishing or finishing processes.

Enhanced Clarity and Brilliance: The precise cuts achieved through diamond wire loop cutting enhance the crystal’s clarity and brilliance, showcasing its natural beauty.

5.Reduced Risk of Damage

Minimized Fractures: Diamond wire loop cutting minimizes the risk of fractures and chipping, ensuring the integrity of the colored crystals.

Less Heat Generation: Im Vergleich zu herkömmlichen Schneidmethoden, diamond wire loop cutting generates less heat, reducing the likelihood of thermal damage to the crystals.

Schlussfolgerung:

In this blog, we have explored the world of colored crystals and their unique characteristics. We have also delved into the revolutionary technique of diamond wire cutting, which offers precise and efficient results. By utilizing diamond wire, professionals can unlock the full potential of colored crystals, enhancing their brilliance and value. Whether it’s sapphires, emeralds, rubies, or amethysts, diamond wire cutting has become an indispensable tool in the world of crystal fabrication. As the demand for custom-cut colored crystals continues to rise, diamond wire cutting will undoubtedly play a pivotal role in meeting these requirements, revolutionizing the industry and inspiring new possibilities for creativity and design.

If you have any custom requirements, we have a dedicated research team that can provide ODM (Original Design Manufacturing) services. We invite you to contact us for further consultation.