Delving Deep into Ensolltools’ Silicon Wafer Cutting Machine

This blog primarily aims to introduce Ensolltools‘ silicon wafer cutting machine, which not only cuts silicon wafers but also various other materials such as ceramic rods, quartz, and crystal.

The Origin of Ensolltools’ Silicon Wafer Cutting Machine

Our ESG300 diamond wire cutting machine has a wide range of applications and can be used to cut various hard and brittle materials. While it is particularly friendly for cutting silicon rods, it is commonly referred to as a silicon ingot cutting machine. In reality, this machine can cut not only silicon ingots but also various other hard and brittle materials. Let’s not be limited by the product’s name.

Our ESG300 diamond wire cutting machine has a wide range of applications and can be used to cut various hard and brittle materials. While it is particularly friendly for cutting silicon rods, it is commonly referred to as a silicon ingot cutting machine. In reality, this machine can cut not only silicon ingots but also various other hard and brittle materials. Let’s not be limited by the product’s name.

Types of Materials that can be Cut

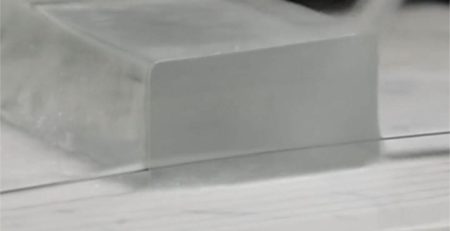

The diamond wire saw machine excels at cutting a variety of materials, with a special emphasis on ceramic rods and quartz. It is proficient in cutting materials like hard alloy blanks, silicon carbide ceramics, polycrystalline silicon, magnetic material strips, optical fiber light guides, and more.

When it comes to ceramic rods, the diamond wire saw machine excels in precision cutting of these cylindrical ceramic components, ensuring clean and accurate cuts that are vital for various industrial applications.

Regarding quartz, the machine’s cutting capabilities extend to this hard and brittle material, allowing for precise shaping and slicing of quartz components with efficiency and accuracy. The diamond wire saw machine’s versatility in handling both ceramic rods and quartz underscores its significance in diverse manufacturing and processing environments.

Why Choose to Cut Silicon Ingots with ESG300

Design Advantages:

Choosing the ESG300 for silicon ingot cutting offers distinct advantages. The ESG300-4T diamond wire saw machine is specifically designed for silicon cut-off operations. It utilizes a diamond wire loop or endless diamond wire as the cutting blade, which is significantly smaller than a diamond band saw. This design minimizes the risk of silicon edge breakage, effectively reducing the rate of defective products.

Cutting Method:

Operating in a vertical cutting manner, this machine features a clamping device tailored for silicon ingots. The inclusion of moving rollers and an air pressure clamp ensures the integrity of the silicon ingots, safeguarding them from damage during the cutting process. For further insights into our silicon diamond wire saw series and to explore additional information, feel free to reach out to us.

Summarize

While this machine is designed to be particularly friendly for silicon cutting, it is also capable of cutting similar hard and brittle materials. Its design is especially accommodating for cylindrical rods, making it a versatile diamond wire cutting machine that can effectively cut a variety of materials.