Diamond Wire Saw Machine for Cutting and Grinding Bricks

Introduction:

Diamond wire saw machines have revolutionized the way we cut and grind materials like bricks. Their precision and efficiency make them indispensable tools in various industries. In this blog post, we will delve into the world of grinding bricks, the intricacies of diamond wire saw machines, and the essential components that make them work seamlessly.

1. Understanding Grinding Bricks

1.1 Hardness:

- Brick hardness is a fundamental property that directly influences its suitability for cutting and grinding applications. Hardness in bricks is primarily determined by the composition of the raw materials used in their manufacture. Commonly, bricks are made from clay and shale, which are fired at high temperatures to form a dense, hard material.

- The hardness of bricks is typically measured using the Mohs scale or the Brinell scale. Bricks generally fall within a range of 5 to 8 on the Mohs scale, indicating a moderate to high level of hardness. This hardness is essential for withstanding the cutting and grinding forces applied during processing without crumbling or breaking apart.

- When selecting tools for cutting and grinding bricks, such as diamond wire saw machines, the hardness of the bricks must be taken into consideration. Harder bricks require tools with abrasives of higher strength and durability to ensure efficient and precise cutting without compromising the structural integrity of the material.

1.2 Characteristics:

In addition to hardness, the characteristics of bricks play a crucial role in their grinding and cutting properties. Bricks exhibit several unique features that impact their behavior during processing:

- Porosity: The porosity of bricks refers to the presence of small openings or pores within the material. Higher porosity can affect the effectiveness of cutting and grinding processes by influencing the absorption of water-based lubricants or cooling agents.

- Texture: The surface texture of bricks can vary depending on the manufacturing process and the type of finish applied. Smooth textures are generally easier to cut and grind compared to rough or irregular surfaces, which may require specialized tools for optimal results.

- Composition: The composition of bricks, including the type of clay or shale used, the firing temperature, and any additives, can influence their density, strength, and overall suitability for cutting and grinding operations. Bricks with uniform composition and minimal impurities are preferred for precise processing.

2. Understanding Diamond Wire Saw Machines

2.1 Diamond Wire Saw Hardness

Diamond wire saws are engineered with diamond-coated wires renowned for their exceptional hardness and resistance to abrasion. The hardness of these wires is critical for their performance in cutting through robust materials like bricks with unparalleled precision and finesse.

The diamond coating ensures durability and longevity, allowing the wire saws to maintain their cutting edge even when subjected to high-stress applications.

2.2 Diamond Wire Saw Characteristics

Diamond wire saw machines are distinguished by their versatility, offering a spectrum of cutting and grinding capabilities. These machines deliver seamless and accurate cuts, significantly reducing material wastage and enhancing operational efficiency.

Their adaptability to a wide range of materials, including bricks, underscores their significance in modern construction and manufacturing domains. By leveraging the advanced features of diamond wire saw machines, industries can achieve superior cutting and grinding outcomes while optimizing resource utilization and productivity.

3. Diamond Wire Saw Machine Components

Diamond wire saw machines consist of several key components, each playing a vital role in the cutting and grinding processes. Some essential components include:

- Diamond Wire: The cutting edge of the machine, coated with industrial-grade diamonds for enhanced cutting precision.

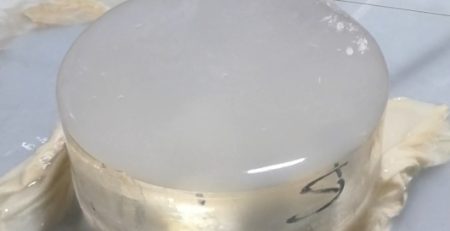

Polyurethane Wheels: Used for guiding the diamond wire and ensuring smooth movement during cutting and grinding operations.

Polyurethane Wheels: Used for guiding the diamond wire and ensuring smooth movement during cutting and grinding operations.

By understanding the properties of bricks, the intricacies of diamond wire saw machines, and the significance of essential components like diamond wire and polyurethane wheels, we can appreciate the precision and efficiency these machines bring to the cutting and grinding of bricks.

By understanding the properties of bricks, the intricacies of diamond wire saw machines, and the significance of essential components like diamond wire and polyurethane wheels, we can appreciate the precision and efficiency these machines bring to the cutting and grinding of bricks.

Summarize:

By understanding the properties of bricks, the intricacies of diamond wire saw machines, and the significance of essential components like diamond wire and polyurethane wheels, we can appreciate the precision and efficiency these machines bring to the cutting and grinding of bricks.