Guía completa de las características y aplicaciones de los bucles de hilo diamantado

1.¿Qué es el bucle de alambre de diamante??

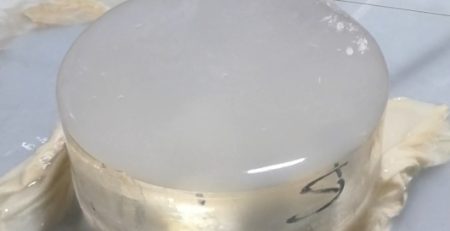

Bucle de alambre de diamante, También conocidas como sierras de hilo diamantado, are cutting tools that consist of a continuous loop of wire embedded with diamond beads. El proceso de fabricación implica la selección de materiales de alta calidad, Unir las cuentas de diamante en el bucle de alambre utilizando técnicas avanzadas, y garantizar un espaciado uniforme para un rendimiento de corte uniforme. Esta innovadora tecnología ofrece capacidades de corte precisas y eficientes en diversas industrias.

2.Nuestros tipos de bucle de alambre de diamante

2.1 Bucle de alambre de diamante totalmente recubierto:

Our fully coated diamond wire loop are designed with diamond beads that are fully coated around the entire circumference of the wire loop. This coating ensures consistent cutting performance and increases the overall lifespan of the wire loop. The even distribution of diamond beads along the wire loop allows for precise and efficient cutting across various materials.

2.2 Segmented Diamond Wire Loop:

2.2 Segmented Diamond Wire Loop:

Our segmented diamond wire loop feature diamond beads placed at regular intervals along the wire loop. This design allows for faster cutting speeds and efficient debris removal. The segmented arrangement of diamond beads ensures a smooth and continuous cutting process, making it ideal for applications where high cutting speeds and precision are required.

Both types of diamond wire loop are crafted with the utmost attention to detail and quality. They are designed to provide exceptional cutting performance, durability, and versatility for a wide range of cutting applications.

Both types of diamond wire loop are crafted with the utmost attention to detail and quality. They are designed to provide exceptional cutting performance, durability, and versatility for a wide range of cutting applications.

3.How to Choose the Diamond Wire Loop Diameter

When selecting the diamond wire loop diameter for your cutting needs, consider the hardness of the material you will be cutting. We offer three cutting solutions based on material hardness:

3.1 For softer materials, it is advisable to choose a thicker diamond wire loop. The increased number of diamond beads helps generate more cutting debris, enhancing the cutting efficiency.

3.2 For harder materials, a thinner diamond wire loop, such as 0.35mm, is recommended. This reduces material removal and cutting resistance, allowing for smoother and more precise cutting.

3.3 For metal cutting, a thinner diamond wire loop is preferred due to lower cutting resistance and improved efficiency. The choice of diamond wire loop diameter depends on the specific material you need to cut.

4.Advantages of Diamond Wire Loop Cutting over Saw Cutting

4.1 Diamond wire loops provide rigid cutting, minimizing material deformation. The rigidity of the diamond wire loop is measured in length, allowing for precise and controlled cutting. This results in a smaller kerf, or the width of the cut, compared to saw cutting. The smaller kerf size makes diamond wire loop cutting ideal for cutting hard and brittle materials without chipping or causing excess damage.

4.2 Smaller kerf sizes are achievable with diamond wire loops, ranging from 0.5mm to 0.25mm, whereas saw cutting typically has kerf sizes of 1mm or larger. This smaller kerf size translates to reduced material waste and higher cutting accuracy, making diamond wire loop cutting a more efficient and cost-effective option.

4.3 Diamond wire loop cutting equipment has a simpler structure compared to traditional saw cutting equipment. The diamond wire loop cutting process is more straightforward and easier to operate. This simplicity also contributes to lower power consumption, making diamond wire loop cutting more energy-efficient and environmentally friendly.

4.4 Diamond wire loop cutting enables 360-degree cutting in all directions, allowing for greater flexibility and versatility in cutting operations. In contrast, saw cutting is limited to single-direction cutting, making it challenging to achieve complex shapes and corner cuts. Diamond wire loop cutting excels in applications that require intricate and precise cutting, such as cutting curves, angles, and irregular shapes.

4.5 Diamond wire loops have a longer cutting lifespan compared to saw blades. The diamond beads embedded in the wire loop are highly durable and resistant to wear and tear. This extended lifespan translates to cost savings and reduced downtime for replacement, making diamond wire loop cutting a more reliable and economical choice.

4.6 Diamond wire loop cutting provides a better cutting surface finish. The continuous motion of the diamond wire loop, combined with the precision of the embedded diamond beads, results in smooth and clean cuts. This superior cutting surface finish reduces the need for additional processing or finishing steps, saving time and resources.

How to Make a Purchase

To make a purchase, please follow the steps below:

1.Visit our website at https://www.ensolltools.com/

2.Browse through our product range to find the Diamond Wire Loop that suits your needs.

3.If you have any questions or need further assistance, click on the “Contáctenos” button to reach out to our sales team.

If you encounter any difficulties or have specific requirements, please feel free to contact our sales team for assistance. We are committed to providing a smooth and satisfactory purchasing experience for our customers.