Guía de selección de sierras de cable para metal

Las sierras de cable para metal son herramientas versátiles ampliamente utilizadas para cortar varios tipos de metales. Se emplean comúnmente en industrias como la construcción, plomería, y automotriz para tareas como cortar tuberías, Barras, y otros objetos metálicos. Este artículo tiene como objetivo proporcionar una guía completa para seleccionar la sierra de cable adecuada para fines de corte de metal.

1.Tipos de sierras de cable

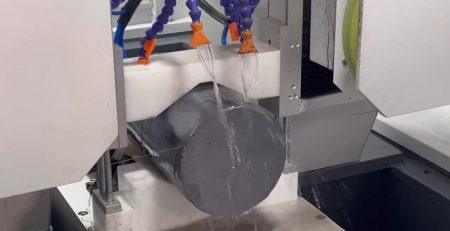

1.1Sierra de alambre de diamante sin fin:El Sierra de alambre de diamante sin fin es una herramienta de corte que utiliza un bucle continuo de alambre recubierto de diamante para el corte de precisión de varios materiales, incluidos los metales, piedras, y materiales compuestos. Esta innovadora tecnología de corte ofrece numerosas ventajas y se ha vuelto cada vez más popular en industrias como la construcción, minería, y manufactura. En este artículo, Profundizaremos en las características, Beneficios, y aplicaciones de la sierra de hilo diamantado sin fin.

1.2 sierra de cable industrial: Las sierras de cable industriales son herramientas robustas diseñadas para aplicaciones de corte de metales de alta resistencia. Por lo general, tienen un motor de alta potencia y un cable reforzado. Las sierras de cable industriales son capaces de cortar tubos metálicos gruesos, Barras, y bares. Ofrecen precisión y velocidad, lo que los hace aptos para uso profesional.

1.3 Sierra de cable manual: Las sierras de cable manuales son herramientas manuales que requieren esfuerzo físico para operar. Son ligeros y portátiles, lo que los hace ideales para tareas de corte de metal a pequeña escala. Las sierras de cable manuales se usan comúnmente para plomería, Proyectos de bricolaje, y situaciones de emergencia.

1.4 sierra de cable de grano de carburo: La sierra de cable de grano de carburo presenta partículas abrasivas o grano de carburo incrustado en la superficie de corte. Este tipo de sierra de cable es adecuada para cortar metales más blandos como el aluminio, cobre, y latón. Las sierras de cable de grano de carburo ofrecen una solución rentable para aplicaciones de corte de metal menos exigentes.

2.Diferencias entre la sierra de hilo de diamante sin fin y la sierra de cable de metal

2.Diferencias entre la sierra de hilo de diamante sin fin y la sierra de cable de metal

Sierra de alambre de diamante sin fin:

- Utiliza un bucle continuo de alambre recubierto de diamante.

- Excelente rendimiento de corte y durabilidad.

- Adecuado para cortar metales duros como acero y acero inoxidable.

- Opción preferida para aplicaciones profesionales.

- Mayor costo en comparación con las sierras de cable de metal.

sierra de cable de metal:

- Puede presentar partículas abrasivas o grano de carburo.

- Adecuado para cortar metales más blandos.

- Proporciona una solución rentable para aplicaciones menos exigentes.

- Menor rendimiento de corte y durabilidad en comparación con las sierras de hilo de diamante sin fin.

- Por lo general, más asequible que las sierras de hilo de diamante sin fin.

3.Selección de una sierra de cable para cortar metal

A la hora de elegir una sierra de cable para cortar metal, Tenga en cuenta los siguientes factores:

3.1Tipo de metal: Determina el tipo de metal que vas a cortar. Si trabajas principalmente con metales duros como el acero, Se recomienda una sierra de hilo diamantado sin fin. Para metales más blandos, Una sierra de cable de metal o una sierra de cable de grano de carburo serán suficientes.

Entendamos los tipos y diferencias entre metales duros y metales blandos

- Metales duros:Metales duros, También conocidos como aleaciones duras o metales de alta resistencia, se caracterizan por sus excelentes propiedades mecánicas, incluyendo alta dureza, fuerza, y resistencia al desgaste. Estos metales tienen una estructura cristalina y suelen estar compuestos por una combinación de elementos, como el hierro, cromo, tungsteno, cobalto, y níquel. Algunos ejemplos de metales duros son el acero, Acero inoxidable, titanio, y carburo de tungsteno.

- Metales blandos:Metales blandos, También conocidos como metales de baja resistencia o metales maleables, poseen una dureza más baja, fuerza, y resistencia al desgaste en comparación con los metales duros. Estos metales tienen una naturaleza más dúctil y flexible, permitiendo que se les dé forma fácilmente, torcido, o estirado. Algunos ejemplos de metales blandos son el aluminio, cobre, Conducir, y estaño.

3.2Requisitos de corte: Evalúe la precisión y la calidad de los cortes que necesita. Las sierras de hilo diamantado sin fin ofrecen un rendimiento de corte superior y son adecuadas para aplicaciones que requieren alta precisión. Para tareas menos críticas, Una sierra de cable de metal o una sierra de cable de grano de carburo pueden proporcionar resultados satisfactorios.

3.2Requisitos de corte: Evalúe la precisión y la calidad de los cortes que necesita. Las sierras de hilo diamantado sin fin ofrecen un rendimiento de corte superior y son adecuadas para aplicaciones que requieren alta precisión. Para tareas menos críticas, Una sierra de cable de metal o una sierra de cable de grano de carburo pueden proporcionar resultados satisfactorios.

3.3Presupuesto: Tenga en cuenta las limitaciones de su presupuesto. Las sierras de hilo diamantado sin fin son generalmente más caras que las sierras de cable de metal. Determine el nivel de rendimiento y durabilidad que necesita y asigne su presupuesto en consecuencia.

3.4Frecuencia de aplicación: Si realiza con frecuencia tareas de corte de metales o tiene requisitos profesionales, Se recomienda invertir en una sierra de cable de alta calidad. Para uso ocasional o de bricolaje, Una opción más asequible puede ser suficiente.

3.5Características de seguridad: Asegúrese de que la sierra de cable seleccionada tenga las características de seguridad adecuadas, como un agarre seguro, Fundas protectoras, y un mecanismo de bloqueo fiable.

Conclusión:

Seleccionar la sierra de cable adecuada para cortar metal es esencial para lograr resultados eficientes y precisos. Ten en cuenta el tipo de metal, Requisitos de corte, presupuesto, Frecuencia de aplicación, y características de seguridad a la hora de tomar su decisión. Las sierras de hilo diamantado sin fin son ideales para cortar metales duros, mientras que las sierras de cable para metal o las sierras de cable de grano de carburo proporcionan soluciones rentables para metales más blandos. Comprendiendo las diferencias y considerando los factores descritos, Puede elegir con confianza la sierra de cable más adecuada para sus necesidades de corte de metal.