Imán de NdFeB cortado con sierra de bucle de alambre de diamante

Diamond wire loop saw cutting NdFeB magnet

Imanes de neodimio, también conocidos como imanes de NdFeB, son cristales tetragonales formados por neodimio, hierro, y boro (Nd2Fe14B). Este tipo de imán es el segundo imán permanente más magnético después del imán de holmio de cero absoluto en la actualidad, Y también es el imán de tierras raras más utilizado.

El NdFeB se divide en dos tipos: NdFeB sinterizado y NdFeB unido. El NdFeB adherido tiene magnetismo en todas las direcciones y es resistente a la corrosión;

El NdFeB sinterizado es fácil de corroer, and the surface needs to be plated. Generalmente, there are galvanized, nickel, environmentally friendly zinc, environmentally friendly nickel, nickel-copper-nickel, and environmentally-friendly nickel-copper-nickel. Sintered NdFeB is generally divided into axial magnetization and radial magnetization, which are determined according to the required working surface.

For cutting large NdFeB magnet, many manufacturers use reciprocating long-wire cutting, while small NdFeB magnet is cut with an Inner diameter cutting machine. The cutting efficiency of the Inner diameter cutting machine is low, but sometimes cutting a small amount of NdFeB magnet does not require turning on a large machine. With the rise of diamond wire loop saw, some manufacturers began to use diamond wire loop saw to cut NdFeB, the cutting efficiency is 3 times that of the Inner diameter cutting machine, which has been welcomed by many manufacturers in China.

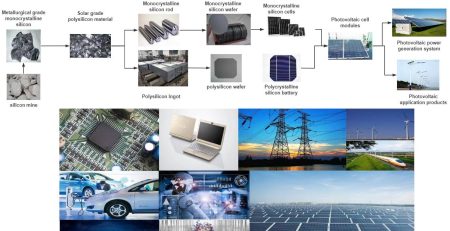

Sintered NdFeB permanent magnet materials have excellent magnetic properties and are widely used in electronics, electrical machinery, Equipos médicos, toys, packaging, hardware machinery, aerospace and other fields.

The more common ones are permanent magnet motors, speakers, magnetic separators, computer disk drives, magnetic resonance imaging equipment and meters.

Below the NdFeB cutting video for reference:

If you want to know more, contact me or leave a message!