¿Por qué el corte de bucle de alambre de diamante puede mejorar la eficiencia de corte y la calidad de la superficie??

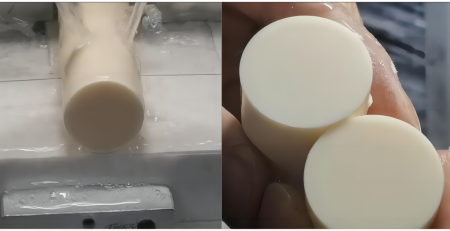

Con el desarrollo continuo de la tecnología, Las ventajas del bucle de hilo diamantado en la industria del procesamiento de corte son cada vez más evidentes. Especialmente en el corte de materiales duros y quebradizos, Su eficiencia de corte es alta, La pérdida de material por colapso de borde es menor, La precisión es alta, La superficie de corte es perfecta, y se elogia al jefe de la industria de procesamiento!

Hay dos razones principales para usar el corte con sierra de hilo de diamante sin fin para mejorar la suavidad de la calidad de la superficie de corte:

Hay dos razones principales para usar el corte con sierra de hilo de diamante sin fin para mejorar la suavidad de la calidad de la superficie de corte:

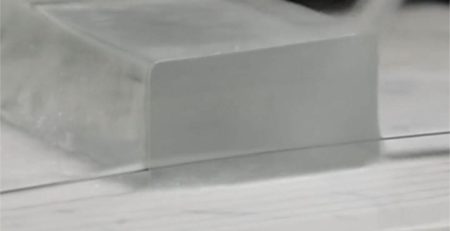

During the design and manufacture of bucle de alambre de diamante, it is necessary to optimize its composition and quality. Specifically, the diamond particles should be electroplated on the wire, and the quality and thickness of the diamond layer and its arrangement should be controlled.

The cutting fluid also plays a key role in maintaining the cutting efficiency of the diamond wire saw. Although the diamond wire loop can be dry cut or wet cut (such as water cut, oil cut), according to the different materials and cutting requirements, adding the right amount of cutting fluid will get a better slicing effect! Overheating can cause diamond degradation, reducing the service life and performance of the line. The cutting fluid can ensure effective heat dissipation in the cutting process, reduce material loss and line marks, thereby improving cutting efficiency.

The cutting fluid also plays a key role in maintaining the cutting efficiency of the diamond wire saw. Although the diamond wire loop can be dry cut or wet cut (such as water cut, oil cut), according to the different materials and cutting requirements, adding the right amount of cutting fluid will get a better slicing effect! Overheating can cause diamond degradation, reducing the service life and performance of the line. The cutting fluid can ensure effective heat dissipation in the cutting process, reduce material loss and line marks, thereby improving cutting efficiency.

Además, compared with the reciprocating cutting wire, the annular continuous diamond cutting wire has only one direction of continuous high-speed movement during the movement, and there is no Reversing mark, which further ensures the cutting quality. Especially in the cutting of high hardness crystal materials, its application prospects are broad. These factors work together to improve the quality smoothness of diamond ring cutting surface. Of course, if you want to know more information, it is recommended to consult Zhengzhou element tool Technology Co., LTD .