NdFeB: Guide de compréhension approfondi

Dans le domaine de la technologie et de l’ingénierie modernes, Les aimants jouent un rôle crucial dans diverses applications. Parmi les nombreux types d’aimants, L’un se distingue par sa force et sa polyvalence remarquables: NdFeB, abréviation de néodyme fer bore. Dans cet article de blog, nous plongerons dans le monde fascinant des aimants NdFeB, explorer leur composition, Propriétés, et applications variées.

La composition des aimants NdFeB:

La composition des aimants NdFeB:

Aimants NdFeB, Également connu sous le nom d’aimants néodyme-fer-bore, are composed of a unique combination of elements that contribute to their exceptional magnetic properties. The composition of NdFeB magnets consists of three main elements: neodymium (Nd), fer (Fe), and boron (B).

Neodymium:

A rare earth element, is the key ingredient that provides NdFeB magnets with their remarkable strength. It possesses a high magnetic moment, meaning it has a strong magnetic field. This characteristic allows NdFeB magnets to generate powerful magnetic forces.

Iron:

Another essential component, contributes to the stability and structure of NdFeB magnets. It helps to maintain the magnet’s magnetic properties over a wide range of temperatures. Iron also aids in aligning the magnetic domains within the magnet, improving its overall magnetic performance.

Boron:

the third element in the composition, plays a crucial role in enhancing the magnetic properties of NdFeB magnets. It helps to increase the coercivity, which is the ability of a magnet to resist demagnetization. The addition of boron allows NdFeB magnets to maintain their magnetization even in the presence of external magnetic fields.

It is worth noting that the composition of NdFeB magnets can vary depending on the specific application and desired magnetic properties. Different ratios of neodymium, fer, and boron, along with the addition of other elements or alloys, can be used to fine-tune the magnet’s characteristics to meet specific requirements.

Versatile Applications:

The unique properties of NdFeB magnets make them indispensable in various industries and technologies. Some notable applications include:

The unique properties of NdFeB magnets make them indispensable in various industries and technologies. Some notable applications include:

- Electric Motors and Generators: NdFeB magnets are extensively used in electric motors and generators due to their high magnetic efficiency. They enable motors to operate at higher speeds while maintaining compact sizes, making them essential components in electric vehicles, wind turbines, and industrial machinery.

- Magnetic Separators: NdFeB magnets are employed in magnetic separation processes to separate and remove ferrous contaminants from materials such as minerals, plastics, and food products. Their strong magnetic fields ensure efficient and precise separation.

- Audio Equipment: NdFeB magnets are commonly found in speakers and headphones, delivering clear and powerful sound reproduction. Their small size and robust magnetic field enable the production of compact and high-fidelity audio devices.

- Magnetic Resonance Imaging (MRI): NdFeB magnets are utilized in MRI machines to generate strong magnetic fields for medical imaging. Their superior magnetic properties contribute to accurate and detailed imaging results.

Manufacturing Challenges:

Despite their exceptional magnetic properties, the manufacturing of NdFeB magnets presents certain challenges that need to be addressed. These challenges arise from both the composition of the magnets and the properties of the individual elements involved.

- One of the primary challenges in the manufacturing of NdFeB magnets is the sourcing and extraction of neodymium, which is a rare earth element. Neodymium reserves are limited, and their extraction involves complex and environmentally sensitive processes. The demand for neodymium in various industries, including the production of NdFeB magnets, necessitates responsible sourcing practices and efforts to minimize environmental impact.

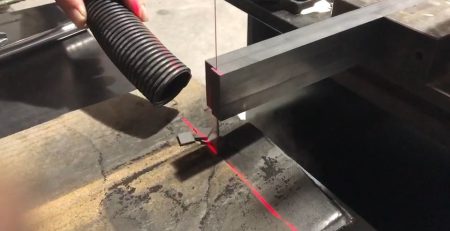

- Furthermore, the production of NdFeB magnets involves handling and processing brittle materials. Neodymium and boron are particularly brittle elements, making the manufacturing process delicate and requiring careful handling to prevent damage to the magnets. Specialized techniques, such as powder metallurgy and sintering, are employed to shape and form the magnets into their desired configurations.Alternatively, NdFeB magnets can be cut into desired shapes using fil diamanté loop

- Another challenge is the susceptibility of NdFeB magnets to corrosion. Iron, one of the main components of NdFeB magnets, is prone to oxidation when exposed to moisture and certain environments. To mitigate this issue, protective coatings or plating, such as nickel or epoxy, are applied to the magnets to enhance their resistance to corrosion and improve their overall durability.

- The high magnetic strength of NdFeB magnets also poses challenges during the manufacturing process. The magnets can attract and cling to metal surfaces, making handling and assembly more complex. Specialized tools and equipment, as well as careful magnetization procedures, are required to ensure precise magnet placement and prevent unintended magnet interactions.

Conclusion:

NdFeB magnets have revolutionized various industries with their extraordinary magnetic properties. Their immense strength, coupled with versatility, has made them indispensable in applications ranging from electric motors and generators to audio equipment and medical imaging. As technology continues to advance, NdFeB magnets will undoubtedly play an increasingly vital role in shaping our modern world