Selecting the Best Cutting Guide for Spring Steel Pipes

Before delving into the specifics of finding the best cutting guide for spring steel pipes, it’s crucial to have a solid understanding of the cutting methods available for this material. Spring steel pipes are known for their hardness and durability, which necessitates specialized cutting techniques for precision and efficiency.

Cutting Methods for Spring Steel Pipes

Cutting Methods for Spring Steel Pipes

- Cut-Off Saw: Utilizing a cut-off saw equipped with an abrasive wheel or high-speed steel blade is a common method for cutting spring steel pipes. This method ensures clean and precise cuts, suitable for various pipe diameters.

- Band Saw Cutting: Band saws with bi-metal or carbide-tipped blades are effective for cutting spring steel pipes. They offer versatility in cutting angles and are ideal for thicker pipes or large-scale operations.

- Plasma Cutting: Plasma cutting is a high-speed method suitable for cutting spring steel pipes of various thicknesses. It provides clean cuts with minimal heat-affected zones, making it ideal for intricate designs or quick production requirements.

- Laser Cutting: Laser cutting offers precision and intricate cutting capabilities for spring steel pipes. This method is suitable for maintaining tight tolerances, intricate shapes, and high-volume production.

- Waterjet Cutting: Waterjet cutting is a versatile method for cutting spring steel pipes without creating heat-affected zones. It is ideal for materials sensitive to high temperatures and allows for cutting complex shapes with high precision.

In addition to the aforementioned cutting techniques, there is another advanced method: Boucle de fil de coupe diamant.

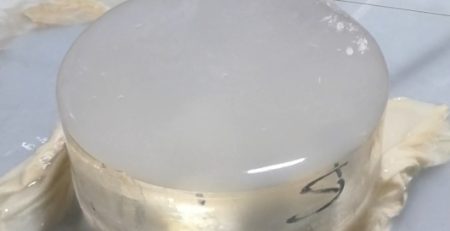

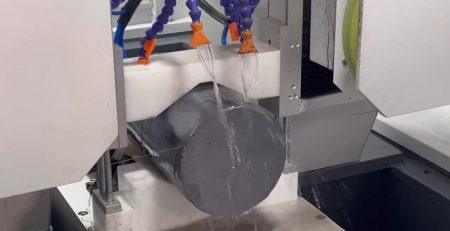

Boucle de fil de coupe diamant: This cutting method involves using a wire loop embedded with diamond particles to cut through spring steel pipes. The diamond cutting wire loop offers high precision and efficiency, making it ideal for intricate cuts and maintaining the structural integrity of the material. This technique is particularly suitable for applications where minimal material loss and high-quality finishes are essential. The use of diamond cutting wire loop technology represents a cutting-edge approach in the processing of spring steel pipes, ensuring precise and clean cuts for various industrial requirements.

Boucle de fil de coupe diamant: This cutting method involves using a wire loop embedded with diamond particles to cut through spring steel pipes. The diamond cutting wire loop offers high precision and efficiency, making it ideal for intricate cuts and maintaining the structural integrity of the material. This technique is particularly suitable for applications where minimal material loss and high-quality finishes are essential. The use of diamond cutting wire loop technology represents a cutting-edge approach in the processing of spring steel pipes, ensuring precise and clean cuts for various industrial requirements.

Steps to Find the Best Cutting Guide for Spring Steel Pipes

- Research the Cutting Techniques: Begin by researching various cutting techniques suitable for spring steel pipes. Understand the pros and cons of each method, with a specific focus on diamond wire saw cutting for its effectiveness with hard materials.

- Identify Suitable Manufacturers for Sample Cutting: Look for reputable manufacturers or service providers that specialize in diamond wire saw cutting services for spring steel pipes. Reach out to these companies to inquire about their capabilities and request sample cutting services.

- Comparative Testing of Samples: Once you receive sample cuts from different manufacturers, conduct a thorough comparative analysis. Evaluate factors such as cutting precision, surface finish quality, and overall efficiency of the cutting process.

Engage in Trial Cutting with Us

Ensoll boasts a proficient team of engineers who offer complimentary trial cutting services. We are a cutting factory that specializes in hard and brittle materials. Our expertise lies in precision cutting techniques tailored to meet the unique demands of materials like spring steel pipes.

By collaborating with Ensoll, you gain access to cutting-edge technologies and the skill of our experienced engineers. We provide a comprehensive trial cutting service that allows you to assess the quality and precision of our cutting processes firsthand. Our commitment to excellence ensures that your spring steel pipes are cut with utmost accuracy and efficiency.

Reach out to us today to schedule your trial cutting session and experience the superior cutting solutions that Ensoll has to offer.