Quels sont les avantages de la coupe en boucle de fil par rapport à la coupe en fil long ??

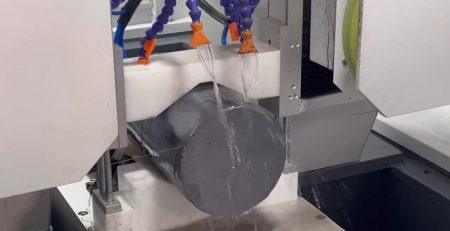

La coupe de boucle de fil en tant que nouvelle technologie de coupe utilisant le traitement de coupe de boucle de fil revêtue de diamant:

Avantages de la découpe en boucle de fil diamanté:

Haute précision: Coupe de boucle de fil diamanté can achieve high precision processing, especially for complex shapes and small size parts have significant advantages.

Good quality: Because the Wire loop cutting is non-contact processing, it will not produce force on the parts and avoid the deformation of the parts. En même temps, the machining surface has high finish, less burrs and good surface quality.

Wide range of materials: Wire loop cutting is suitable for various hardness materials, including cemented carbide, céramique, metals, etc., with strong adaptability.

Large cutting thickness: Boucle de fil diamanté cutting can process larger thickness of the workpiece, and is not affected by the hardness of the material.

Small thermal impact on the workpiece: Because the heat generated in the ring cutting process is mainly concentrated in the cutting joint, the thermal impact on the workpiece is small, which is conducive to maintaining the dimensional stability of the workpiece.

No tool wear: Because the Wire loop cutting is non-contact processing, the electrode wire does not directly contact the workpiece, so there is no tool wear, which is conducive to maintaining the processing accuracy.

Suitable for processing complex CNC curves, special-shaped cutting: Diamond wire loop cutting machining can realize the processing of complex CNC curves, and the processing shape is flexible.