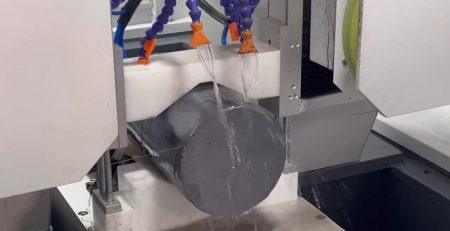

How about diamond looped wire saw cutting ceramics?

Diamond looped wire cutting technology has demonstrated outstanding performance in the field of ceramic processing, bringing a revolutionary transformation to the ceramics manufacturing industry. This efficient and precise cutting method not only significantly improves production efficiency but also opens up new possibilities for the fine processing of ceramic products.

Traditional ceramic processing methods often face challenges due to the high hardness and brittleness of ceramic materials, making it difficult to achieve precise and intricate machining with conventional cutting tools. However, diamond looped wire cutting technology has successfully overcome these issues through its remarkable hardness and wear resistance. As a cutting tool, diamond maintains high cutting quality and can sustain its cutting efficiency for longer durations, greatly enhancing the processing efficiency of ceramic products.

The technology’s precision has injected new vitality into the ceramic industry. With diamond looped wire cutting achieving cutting precision at the micrometer level, it can carve out exquisite and intricate ceramic structures, elevating the appearance and texture of ceramic products to a higher level. This is particularly advantageous in fields that demand highly refined processing, such as the manufacturing of ceramic artworks and precision ceramic components.

The technology’s precision has injected new vitality into the ceramic industry. With diamond looped wire cutting achieving cutting precision at the micrometer level, it can carve out exquisite and intricate ceramic structures, elevating the appearance and texture of ceramic products to a higher level. This is particularly advantageous in fields that demand highly refined processing, such as the manufacturing of ceramic artworks and precision ceramic components.

Furthermore, the efficiency of diamond wire cutting technology has brought convenience to the ceramic industry’s production processes. The increased cutting speed not only shortens the processing cycle but also aids in quickly adapting to changes in market demand, making ceramic manufacturers more competitive.

In conclusion, diamond wire cutting technology has showcased its outstanding advantages in ceramic processing, paving the way for new prospects in the ceramics manufacturing industry. The application of this innovative technology not only enhances production efficiency but also provides broader possibilities for the design and manufacturing of ceramic products, propelling the entire ceramic industry towards higher levels of development.