Una guida completa per comprendere i tipi di anelli di filo diamantato

Diamond wire loops are crafted using advanced manufacturing processes where diamonds are embedded onto a wire loop. This intricate process results in durable cutting tools known for their precision and effectiveness in various industries.

Types of Diamond Wire Loops:

Diamond wire loops come in various types tailored for specific cutting applications. Two common types include:

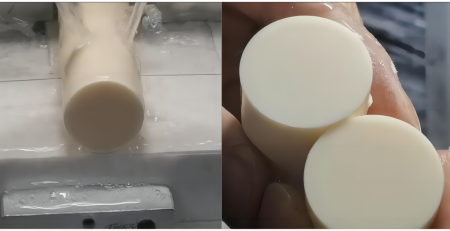

1.Full Plated Diamond Wire Loops:

Full plated diamond wire loops are characterized by a complete coating of diamond particles on the wire surface. This design ensures uniform diamond distribution, providing consistent cutting performance and extended tool life. These loops are ideal for applications requiring continuous and precise cutting, such as slicing hard materials like granite or ceramics.

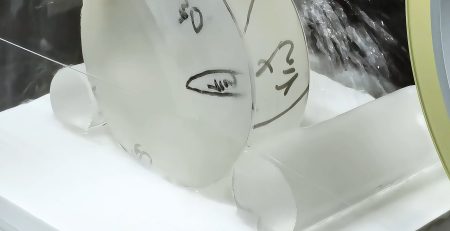

2 Segmented Diamond Wire Loops:

2 Segmented Diamond Wire Loops:

Segmented diamond wire loops feature intermittent segments of diamond coating along the wire. This design allows for efficient debris removal during the cutting process, reducing heat buildup and enhancing cutting speed. Segmented loops are often preferred for cutting softer materials like marble or glass, where smooth and fast cutting is essential.

Each type of diamond wire loop offers unique advantages suited for specific cutting tasks. Choosing the right type depends on factors such as material hardness, cutting precision requirements, and project specifications. By selecting the appropriate type of diamond wire loop, users can optimize cutting efficiency and achieve superior results in their cutting operations.

How to Choose the Right Wire Loop:

Choosing the right wire loop is a critical decision that can significantly impact the success of cutting operations. Here are some key factors to consider when selecting a wire loop:

- Material Compatibility: Different wire loops are designed for specific materials. Consider the hardness and composition of the material you intend to cut to ensure the wire loop’s diamond grit size and bonding type are suitable for the task.

- Cutting Precision: The level of precision required in your cutting project will influence your choice of wire loop. For intricate or detailed cutting tasks, opt for a wire loop with fine diamond grit and a durable bonding agent.

- Cutting Speed: The cutting speed needed for your project is another crucial factor. Segmented wire loops are preferred for faster cutting speeds, while full-plated loops offer more consistent cutting results.

- Budget and Longevity: Evaluate the cost-effectiveness and durability of the wire loop. While full-plated loops may have a longer lifespan, segmented loops are more cost-effective for certain applications.

- Consultation: Seek advice from experienced professionals or technical consultants in the field of cutting tools. Their expertise can help you navigate the options available and choose the most suitable wire loop for your specific requirements.

- Trial Runs: Conducting trial runs with different types of wire loops can provide valuable insight into their performance and suitability for your cutting needs. This hands-on approach can help you make an informed decision based on practical results.

Purchasing Diamond Wire Loops:

When purchasing diamond wire loops, it is essential to source them from reputable suppliers to ensure quality and performance. One recommended platform for acquiring high-quality diamond wire loops is Ensoll Tools (https://www.ensolltools.com/). They offer a wide range of diamond tools, including wire loops, known for their precision, durabilità, and efficiency in various cutting applications.

In conclusione, understanding the different types of diamond wire loops and selecting the right one for your cutting needs can significantly impact the success of your projects. By consulting with experts and purchasing from trusted suppliers like Ensoll Tools, you can ensure that you have the appropriate tools to achieve precise and efficient cutting results.