Vantaggi del taglio con sega a filo diamantato ad anello rispetto ad altri utensili da taglio

La sega da taglio a filo diamantato ad anello presenta molteplici vantaggi rispetto ad altri utensili da taglio, making it the preferred cutting tool in various fields. Here are the key advantages of diamond wire saw cutting over other cutting tools:

Hardness and Wear Resistance: Diamond is one of the hardest materials in nature, giving diamond wire cutting excellent hardness and wear resistance. Compared to other cutting tools, diamond wire cutting can better resist material wear, extending the tool’s lifespan.

High Precision: Diamond looped wire cutting saw exhibits high precision, allowing for fine cutting of materials. This makes it widely used in fields such as gemstone processing and scientific experiments that require high precision.

High Precision: Diamond looped wire cutting saw exhibits high precision, allowing for fine cutting of materials. This makes it widely used in fields such as gemstone processing and scientific experiments that require high precision.

Versatility Across Materials: Diamond looped wire saw cutting is suitable for various materials, including metals, ceramica, gemstones, vetro, and more. Relative to other cutting tools, it performs exceptionally well when dealing with different types of materials.

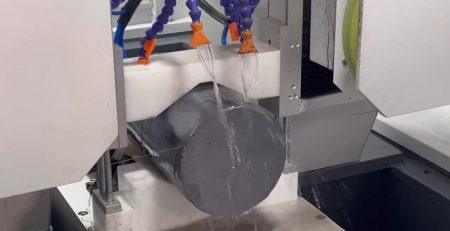

Efficient Cutting: Diamond wire looped cutting employs a rotating method, enabling efficient cutting processes. This increases production efficiency and reduces cutting time in industrial manufacturing.

Maintaining Material Integrity: Due to the hardness and high precision of diamond, diamond looped wire cutting can maintain the integrity of materials during the cutting process, preventing damage or cracks.

Maintaining Material Integrity: Due to the hardness and high precision of diamond, diamond looped wire cutting can maintain the integrity of materials during the cutting process, preventing damage or cracks.

Cutting Surface Quality: Diamond looped wire saw cutting produces high-quality cutting surfaces, minimizing burrs or rough surfaces. This makes it favorable in applications that require high-quality cutting.

In sintesi, the advantages of diamond wire cutting lie in its hardness, resistenza all'usura, Alta precisione, and broad applicability, making it an ideal cutting tool in many industries.