Diamond Wire Saw Cutting Tungsten Rods

In the realm of cutting materials as tough as tungsten rods, the diamond wire saw emerges as a formidable tool. This article delves into the intricacies of diamond wire saw cutting, exploring its significance and effectiveness in shaping tungsten rods.

1.Understanding Diamond Wire Saw:

1.Understanding Diamond Wire Saw:

Diamond wire saws represent a pinnacle in cutting technology, harnessing the power of diamond-embedded wires to slice through the toughest materials with unparalleled precision. In this detailed exploration, we delve into the inner workings of diamond wire saws, their applications, and the unique advantages they offer in the realm of cutting technology.

1.1Applications of Diamond Wire Saws:

1.1Applications of Diamond Wire Saws:

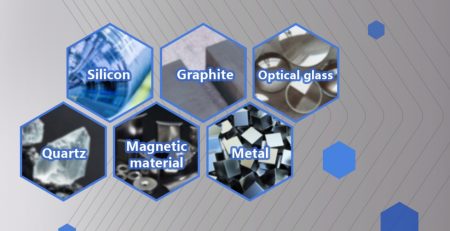

Diamond wire saws find extensive use across various industries, including mining, construction, semiconductor manufacturing, and aerospace. In the mining sector, diamond wire saws are employed for quarrying operations, cutting through hard rock formations with precision and efficiency. In the construction industry, these tools are indispensable for cutting concrete, reinforced steel, and other challenging materials. Moreover, in the semiconductor and electronics sectors, diamond wire saws are utilized for wafer dicing and precision cutting of brittle materials like silicon.

1.2Key Advantages of Diamond Wire Saw Technology:

- Precision Cutting: The diamond particles on the wire provide a sharp and consistent cutting edge, ensuring precise cuts with minimal material wastage.

- Enhanced Efficiency: Diamond wire saws operate at high speeds, facilitating rapid and efficient cutting processes.

- Minimal Material Loss: The thin kerf produced by diamond wire saws results in minimal material loss, maximizing yield and reducing costs.

- Clean Cuts: Diamond wire saws produce smooth and clean cuts, eliminating the need for additional finishing processes.

- Versatility: Diamond wire saws can be customized to cut a wide range of materials, making them versatile tools in various industries.

2.Why Use Diamond Wire Saw for Cutting Tungsten Rods:

2.1Exceptional Hardness of Diamond:

Diamonds are renowned for being one of the hardest substances known to man. When these diamond particles are embedded on a wire to form a diamond wire saw, they create a cutting tool that can effortlessly slice through the extreme hardness of tungsten. The exceptional hardness of diamonds ensures that the wire maintains its sharp cutting edge even when subjected to the abrasive nature of tungsten, resulting in clean and precise cuts.

2.2Minimal Heat Generation:

One of the key challenges when cutting tungsten is the generation of heat, which can lead to material distortion and reduce cutting precision. Diamond wire saws offer a solution to this problem by minimizing heat generation during the cutting process. The efficient cutting action of the diamond particles on the wire reduces friction, thereby keeping the temperature of the cutting area low and preserving the integrity of the tungsten rod.

2.3Precision and Accuracy:

Tungsten rods are often used in applications where precision and accuracy are critical. Diamond wire saws excel in delivering precise cuts with tight tolerances, making them ideal for shaping tungsten rods according to exact specifications. The sharpness and consistency of the diamond cutting edge ensure that the cuts are clean and uniform, maintaining the structural integrity of the tungsten rod.

2.4Longevity and Durability:

Diamond wire saws are known for their longevity and durability, even when cutting through tough materials like tungsten. The resilience of the diamond particles ensures that the wire maintains its cutting efficiency over extended periods of use, reducing the need for frequent replacements and resulting in cost savings in the long run.

3.Cutting Effectiveness of Diamond Wire Saw:

3.1Continuous Sharp Cutting Surface:

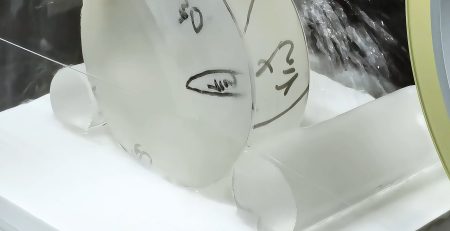

The key to the cutting effectiveness of diamond wire saws lies in their ability to maintain a continuous sharp cutting surface throughout the cutting process. The diamond particles embedded on the wire ensure a consistent and uniform cutting edge, allowing the saw to effortlessly slice through tough materials like tungsten rods. This continuous sharpness minimizes material wastage and results in clean, precise cuts with smooth finishes.

3.2Minimized Material Distortion:

Unlike traditional cutting methods that can cause heat buildup and material distortion, diamond wire saw cutting offers a solution that preserves the integrity of the material being cut. When cutting tungsten rods, for example, the minimal heat generation and precise cutting action of diamond wire saws help prevent material distortion, ensuring that the tungsten retains its structural properties and dimensional accuracy.

3.3Reduced Kerf Width:

The thin kerf produced by diamond wire saws contributes to their cutting effectiveness by minimizing material loss during the cutting process. The narrow cutting path created by the diamond wire results in reduced waste and maximizes the yield of usable material from the tungsten rod. This efficiency not only saves costs but also enhances the overall productivity of the cutting operation.

3.4Smooth and Clean Cuts:

Diamond wire saw cutting is known for its ability to produce smooth and clean cuts, free from burrs or rough edges. The precision of the cutting process ensures that the surfaces of the tungsten rods remain pristine and free of imperfections. This level of cutting quality is crucial in industries where precise dimensions and surface finishes are essential for the performance of the final product.

Conclusion:

In conclusione, the utilization of diamond wire saws for cutting tungsten rods signifies a significant advancement in cutting technology. The unparalleled hardness and durability of diamond grains make these tools indispensable for industries requiring precise and efficient cutting processes. With the ability to achieve clean cuts and maintain material integrity, diamond wire saws stand out as the go-to choice for shaping tough materials like tungsten rods.