Risolvere i punti deboli del settore: I vantaggi della sega a filo diamantato senza fine nel settore del taglio

In today’s rapidly evolving technological landscape, L'industria del taglio svolge un ruolo cruciale in vari settori, compresa la costruzione, manifatturiero, and mining. Tuttavia, traditional cutting methods often encounter several pain points, hindering efficiency, precision, and cost-effectiveness. In this blog, we will explore the challenges faced in the cutting domain and shed light on the remarkable advantages of the sega a filo diamantato senza fine, a revolutionary cutting tool.

1.Industry Pain Points:

1.Industry Pain Points:

1.1 Time-consuming Process:

Traditional cutting techniques such as sawing, macinatura, and abrasive cutting often require substantial time investments due to their limitations in speed, precision, and material adaptability.

1.2 Inefficiency and Material Loss:

Conventional cutting methods are often associated with significant material wastage due to their inability to minimize kerf width, resulting in increased costs and environmental concerns.

1.3 Limited Cutting Range:

Many cutting tools have limitations when it comes to cutting different materials, especially hard and brittle ones. This hampers productivity and restricts the possibilities for various industries.

1.4 Safety Concerns:

Manual cutting processes, such as using handheld saws or abrasive discs, can pose significant safety risks for operators due to the potential for accidents, injuries, and exposure to harmful dust or fumes.

2.The Advantages of Endless Diamond Wire Saw:

2.1 Enhanced Cutting Speed:

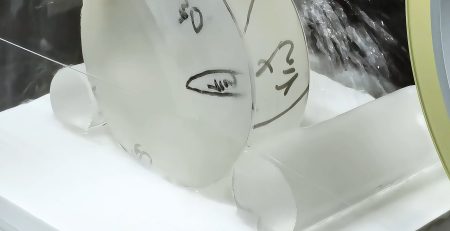

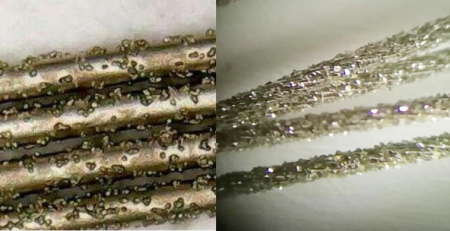

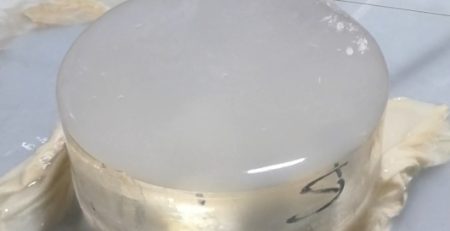

The sega a filo diamantato senza fine revolutionizes the cutting industry by significantly increasing cutting speed compared to traditional methods. This is achieved through the use of a thin, continuous wire embedded with diamond beads that efficiently cuts through various materials, including stone, metallo, vetro, and composites.

2.2 Precision and Reduced Kerf Width:

Endless diamond wire saws offer exceptional precision, allowing for intricate cuts with minimized kerf width. This not only optimizes material utilization but also reduces post-cutting processing requirements, saving time and costs.

2.3 Versatility and Material Adaptability:

With the ability to cut through a wide range of materials, the endless diamond wire saw eliminates the need for multiple cutting tools. From delicate glass to robust metal alloys, this cutting innovation can adapt to various materials, enhancing productivity and versatility.

2.4 Increased Safety:

Endless diamond wire saws prioritize operator safety. With a controlled cutting process and reduced manual intervention, the risks associated with traditional cutting methods, such as accidents and exposure to hazardous substances, are significantly minimized.

2.5 Cost-effectiveness:

By minimizing material wastage, reducing processing time, and streamlining operations, endless diamond wire saws offer tangible cost savings for industries. The efficiency and precision of this cutting tool translate into improved productivity and reduced overheads.

Conclusion:

The cutting industry has long grappled with pain points that hinder efficiency, precision, and safety. Tuttavia, the emergence of the endless diamond wire saw has provided a game-changing solution. By addressing the challenges faced by traditional cutting methods, this cutting-edge technology offers enhanced speed, precision, versatility, safety, and cost-effectiveness. As industries continue to evolve, the endless diamond wire saw stands as a testament to the transformative power of innovative solutions in overcoming industry pain points.