La migliore soluzione per il taglio del neodimio ferro boro: Sega a filo diamantato senza fine

Introduzione:

Quando si tratta di tagliare il neodimio ferro boro (NdFeB), Trovare il metodo migliore è fondamentale. In questo post del blog, we will explore the characteristics of NdFeB material, discuss the optimal cutting techniques, highlight the advantages of using an sega a filo diamantato senza fine, and provide contact information for further assistance.

Understanding NdFeB Material:

Understanding NdFeB Material:

Neodymium iron boron is a type of rare-earth magnet known for its exceptional magnetic properties. It consists of three main elements: neodymium, ferro, and boron. NdFeB magnets are widely used in various industries, including electronics, automobilistico, medical, and renewable energy.

The Best Cutting Techniques for NdFeB Material:

Cutting NdFeB material requires precision and expertise to ensure minimal damage and maximum efficiency. Several cutting methods are available, including sawing, macinatura, and wire cutting. Tuttavia, the endless diamond wire saw has proven to be the most optimal solution due to its unique advantages.

Advantages of the Endless Diamond Wire Saw:

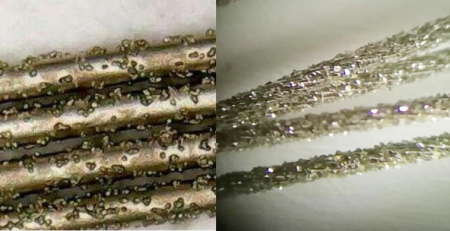

The endless diamond wire saw is a cutting-edge technology that utilizes a thin wire embedded with industrial-grade diamonds. Here are some key advantages of using an endless diamond wire saw for NdFeB material:

The endless diamond wire saw is a cutting-edge technology that utilizes a thin wire embedded with industrial-grade diamonds. Here are some key advantages of using an endless diamond wire saw for NdFeB material:

- Precision: The endless diamond wire saw offers high precision, allowing intricate cuts and shapes to be achieved accurately. This is particularly important when dealing with small or complex NdFeB components.

- Minimal Material Loss: With the endless diamond wire saw, the thin wire minimizes material loss during the cutting process. This is especially beneficial when working with expensive NdFeB material, as it helps to reduce costs.

- Smooth Surface Finish: The endless diamond wire saw provides a smooth surface finish, eliminating the need for additional finishing processes. This saves both time and effort, making it a highly efficient cutting method.

- Reduced Heat Generation: Compared to other cutting techniques, the endless diamond wire saw generates less heat, reducing the risk of material deformation or damage. This ensures the integrity of the NdFeB material is maintained.

- Versatility: The endless diamond wire saw is suitable for cutting NdFeB magnets of various shapes and sizes, making it a versatile cutting solution for different applications.

Contattaci:

For further inquiries or assistance regarding the best cutting solution for NdFeB material, please feel free to reach out to us at [Contact Information]. Our team of experts is ready to provide you with tailored advice and support to meet your specific requirements.

In conclusione, cutting NdFeB material requires careful consideration of the best cutting techniques available. The endless diamond wire saw stands out as the optimal solution due to its precision, minimal material loss, smooth surface finish, reduced heat generation, and versatility. By utilizing the endless diamond wire saw, you can ensure the highest quality cuts for your NdFeB components. Contact us today to explore how we can assist you with your cutting needs.