長いワイヤー切断に対するワイヤーループ切断の利点は何ですか?

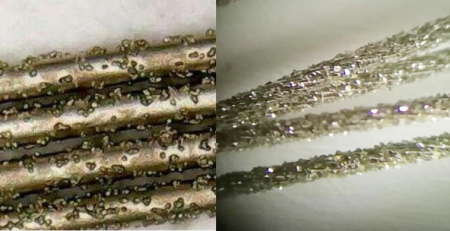

ダイヤモンド被覆ワイヤーループ切断加工による新しい切断技術としてのワイヤーループ切断:

ダイヤモンドワイヤーループ切断の利点:

高精度: ダイヤモンドワイヤーループ切断 can achieve high precision processing, especially for complex shapes and small size parts have significant advantages.

Good quality: ワイヤーループ切断は非接触加工のため, 部品に力が加わらず、部品の変形を防ぎます. 同時に, 加工面は仕上げ性が高い, less burrs and good surface quality.

Wide range of materials: Wire loop cutting is suitable for various hardness materials, including cemented carbide, 陶芸, 金属, 等。, with strong adaptability.

Large cutting thickness: ダイヤモンドワイヤーループ cutting can process larger thickness of the workpiece, and is not affected by the hardness of the material.

Small thermal impact on the workpiece: Because the heat generated in the ring cutting process is mainly concentrated in the cutting joint, the thermal impact on the workpiece is small, which is conducive to maintaining the dimensional stability of the workpiece.

No tool wear: ワイヤーループ切断は非接触加工のため, the electrode wire does not directly contact the workpiece, so there is no tool wear, which is conducive to maintaining the processing accuracy.

Suitable for processing complex CNC curves, special-shaped cutting: Diamond wire loop cutting machining can realize the processing of complex CNC curves, and the processing shape is flexible.