Multi-Angle Diamond Wire Saw Cutting of Quartz Glass

정밀 제조 영역에서, 고급 절단 기술의 활용은 석영 유리와 같은 섬세한 재료를 성형하는 데 중추적인 역할을 합니다. 이러한 기술 중, 이 다이아몬드 와이어 톱 절단기 stands out for its precision and versatility. 이 블로그 게시물에서는, 우리는 석영 유리의 다각도 절단에서 다이아몬드 와이어 톱 절단기의 적용에 대해 탐구합니다, 제조업에 대한 중요성과 영향 탐구.

다이아몬드 와이어 톱 절단기 살펴보기:

다이아몬드 와이어 톱 절단기 살펴보기:

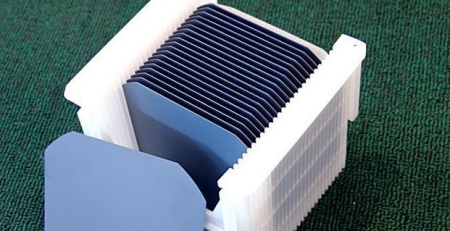

다이아몬드 와이어 톱 절단기, 이름에서 알 수 있듯이, is a cutting tool that utilizes a wire embedded with diamond particles to slice through various materials with exceptional precision. This cutting-edge technology has revolutionized the manufacturing processes by offering high levels of accuracy and efficiency, making it a preferred choice for industries requiring intricate cutting operations.

Significance of Quartz Glass in Manufacturing:

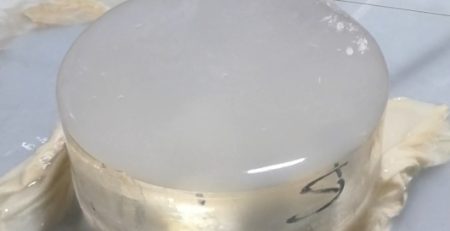

Quartz glass, also known as fused silica, is a unique material prized for its exceptional clarity, high thermal resistance, and chemical inertness. It finds extensive applications in optics, semiconductors, and laboratory equipment due to its superior properties. The ability to cut and shape quartz glass with precision is essential for creating high-quality products in these industries.

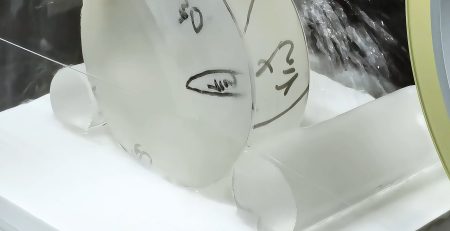

Multi-Angle Cutting of Quartz Glass:

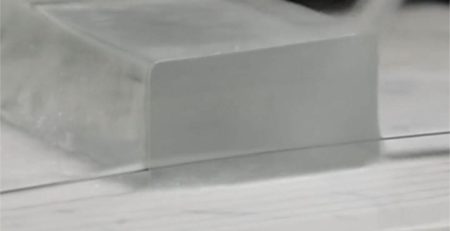

Achieving precise cuts at multiple angles in quartz glass presents a significant challenge due to the material’s brittleness and hardness. Traditional cutting methods often result in chipping or surface imperfections, compromising the quality of the final product. The diamond wire saw cutting machine excels in addressing these challenges by offering a solution that ensures clean cuts at various angles without causing damage to the material.

Advantages of Multi-Angle Diamond Wire Saw Cutting:

- 정밀: The diamond wire saw cutting machine enables precise cutting at different angles, ensuring accuracy in complex designs and patterns.

- 능률: This cutting method minimizes material wastage and reduces the need for extensive post-processing, leading to cost savings for manufacturers.

- 다재: The ability to cut quartz glass at multiple angles opens up new design possibilities and applications in various industries.

- Quality: The clean cuts produced by the diamond wire saw cutting machine result in high-quality products that meet stringent industry standards.

Challenges and Solutions:

While the diamond wire saw cutting machine offers numerous advantages, challenges such as wire wear and control of cutting parameters need to be addressed for optimal results. Manufacturers employ strategies like using high-quality diamond wires, optimizing cutting speeds, and maintaining proper tension to overcome these challenges and ensure consistent cutting performance.

Future Trends in Diamond Wire Saw Cutting:

기술이 계속 발전함에 따라, the application of diamond wire saw cutting machines in the cutting of quartz glass is poised to evolve further. Innovations in wire materials, cutting techniques, and automation are expected to enhance precision and efficiency, opening up new possibilities for manufacturing intricate quartz glass products.

결론:

The diamond wire saw cutting machine has emerged as a cornerstone in the manufacturing industry, particularly in the precise cutting of materials like quartz glass. Its ability to achieve multi-angle cuts with unparalleled precision and efficiency has revolutionized the production of high-quality components for diverse industries. As we look towards the future, the continued advancement of diamond wire saw cutting technology promises to set new standards in precision manufacturing, unlocking innovative possibilities in the fabrication of quartz glass products.