Diamond Looped Wire Saw Cutting in Processing Optical Glass의 전망

다이아몬드 루프 와이어 절단은 광학 유리 가공에 방대한 전망을 가지고 있습니다., 그리고 그 독특한 장점으로 인해 광학 유리 제조 분야에서 중요한 도구가 됩니다. 광학 유리 가공에서 다이아몬드 와이어 절단의 전망은 다음과 같습니다.:

높은 정밀도 및 정밀한 절단: 다이아몬드 와이어 톱 절단, 고정밀 절단 능력과 미세한 작동으로, 광학 유리의 정밀 가공에 적합합니다.. 이는 고정밀 광학 부품 제조에 필수적입니다, 렌즈 포함, 프리즘, and windows.

Flexible Processing of Complex Shapes: Optical glass products often have complex shapes, and the flexibility of diamond wire cutting allows it to adapt to various cutting requirements, including non-spherical lenses and other irregular components.

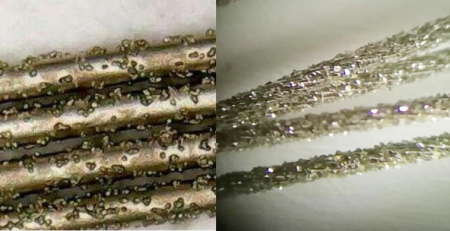

High-Quality Cutting Surface: Diamond wire cutting can produce a high-quality cutting surface, reducing burrs and roughness, ensuring that the surface quality of optical glass components meets the required standards.

High-Quality Cutting Surface: Diamond wire cutting can produce a high-quality cutting surface, reducing burrs and roughness, ensuring that the surface quality of optical glass components meets the required standards.

Reduced Material Waste: Due to the efficiency and precision of diamond wire cutting, the generated cutting residues are relatively minimal, helping to reduce waste of raw materials and improve cost-effectiveness.

Applicable to Various Optical Glass Materials: Diamond wire cutting is suitable for processing various optical glass materials, including special optical glasses with low dispersion, high refractive index, and high transparency. This makes it versatile in manufacturing high-performance optical devices.

Increased Production Efficiency: 다이아몬드 와이어 절단, with its efficient rotating cutting method, significantly improves production efficiency, especially in the mass production of optical components.

요약, 다이아몬드 와이어 절단 has a bright future in processing optical glass, meeting the requirements for high precision, high quality, 그리고 효율성. 기술이 계속 발전함에 따라, diamond wire cutting will continue to play a crucial role in the field of optical glass, driving advancements in optical device manufacturing technology.