Precious Wood Cutting – Unveiling the Cutting Charm of Diamond Wire Loop

Precious woods like rosewood and huanghuali are highly sought after for their rarity, unique texture, and color. To maximize the utilization of these valuable resources and protect the environment, diamond wire loop cutting technology has emerged. This article will introduce the process of diamond wire loop cutting and take you on a journey to appreciate the unique charm of precious woods like rosewood and huanghuali.

Why use diamond wire loop cutting for precious wood:

Why use diamond wire loop cutting for precious wood:

- Efficient cutting: Diamond wire loop cutting technology utilizes cutting loops made from diamond particles to rotate and cut through the wood. This cutting method is fast and precise, greatly improving production efficiency.

- Waste reduction: Diamond wire loop cutting technology minimizes wood waste and enhances wood utilization, aligning with environmental conservation principles.

Advantages of diamond wire loop cutting:

- Efficient cutting: Diamond wire loop cutting technology employs cutting loops made from diamond particles, which rotate at high speed to cut through the wood. Compared to traditional cutting methods, diamond wire loop cutting is faster, enabling the completion of large-scale cutting tasks in a short time, thereby enhancing production efficiency.

- Accommodates complex shapes: The uniqueness of diamond wire loop cutting technology lies in its ability to accommodate complex shape cutting requirements. For special-shaped materials like precious woods, traditional cutting techniques may struggle to accurately achieve the desired shape, whereas diamond wire loop cutting effortlessly meets this challenge.

- High precision: Diamond wire loop cutting technology achieves high-precision cutting by rotating the cutting loop, ensuring accurate wood shape and dimensions. This is crucial for precise processing of precious woods, maximizing wood resource utilization while minimizing waste.

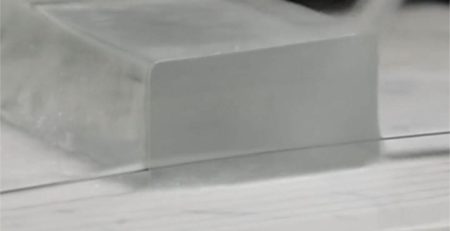

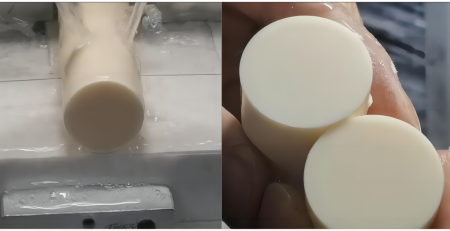

- Smooth cutting surface: Diamond wire loop cutting technology produces smooth and even wood surfaces, minimizing the occurrence of burrs or damage. This is particularly important for precious woods, as their texture and color are integral to their unique charm and need to be preserved.

- Reduced loss: Diamond wire loop cutting technology minimizes wood waste, maximizing wood utilization. The small and precise cutting loops reduce loss during the cutting process, enabling more efficient utilization of precious woods.

- Environmentally friendly and energy-saving: The diamond cutting loops used in diamond wire loop cutting technology possess high hardness and wear resistance, ensuring prolonged usage. Compared to traditional cutting methods, diamond wire loop cutting reduces the frequency of tool replacement, thereby decreasing energy and resource consumption, in line with environmental conservation and energy-saving requirements.

Why choose us:

1.We are a large-scale factory, with more strength than trading companies.

As a factory, we have the advantage of direct production and control over the entire manufacturing process. This allows us to ensure product quality, timely delivery, and competitive pricing. Compared to trading companies, we have a more extensive range of products and are better equipped to handle bulk orders.

2.We have a professional R&D team.

Our dedicated team of engineers and researchers constantly strive to innovate and develop new products. We stay up-to-date with the latest industry trends and technologies, allowing us to offer cutting-edge solutions to meet our customers’ needs. By choosing us, you can benefit from our expertise and access to the latest advancements in cutting technology.

3.We provide reliable after-sales support.

We understand the importance of providing excellent customer service even after the purchase is made. Our professional after-sales team is available 24/7 to address any concerns or issues you may have. We are committed to ensuring your satisfaction and will go the extra mile to resolve any problems promptly.

In summary, by choosing us, you can benefit from our strong manufacturing capabilities, innovative R&D team, and reliable after-sales support. We are dedicated to providing high-quality products and services to meet your cutting needs.