Подробное руководство по пониманию оптического стекла

Обзор:

Оптическое стекло, Специализированный тип стекла с исключительными оптическими свойствами, стоит в авангарде современных технологий и инноваций, playing a pivotal role in a myriad of industries. Its unique characteristics have revolutionized fields ranging from telecommunications to medical imaging, making it an indispensable material in today’s world of precision optics.

In the following sections of this guide, we will delve deeper into the concept of optical glass, exploring its unique properties and the cutting-edge techniques used to shape and refine this remarkable material.

Understanding the Concept of Optical Glass:

Understanding the Concept of Optical Glass:

1. Definition of Optical Glass:

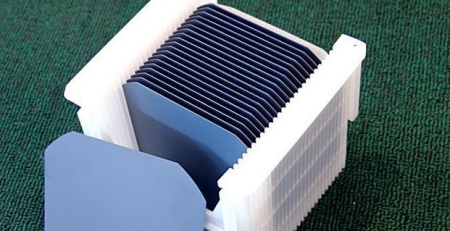

Optical glass is a specialized type of glass engineered for use in optical systems, such as lenses, Призмы, and filters. Unlike regular glass, optical glass is meticulously crafted to exhibit specific optical properties that are essential for manipulating light in precise ways. These properties enable optical glass to play a fundamental role in a wide range of optical instruments and devices.

2. Significance in Optics:

Optical glass is the backbone of modern optics, serving as the building blocks for various optical components that form the basis of advanced imaging systems, Телескопы, Микроскопы, Камеры, and other optical instruments. Its exceptional clarity, uniformity, and refractive index make optical glass indispensable in achieving sharp images, correcting aberrations, and controlling light transmission in optical systems.

3. Distinction from Regular Glass:

One of the key differences between optical glass and regular glass lies in their composition and manufacturing processes. Optical glass is formulated with high precision to have specific refractive indices, dispersion properties, and low impurities to ensure minimal light absorption and precise light manipulation. Regular glass, С другой стороны, is primarily designed for structural purposes and lacks the optical purity required for advanced optical applications.

4. Unique Properties of Optical Glass:

Optical glass exhibits several unique properties that make it ideal for optical applications. These properties include high transmittance of light across a broad spectrum, low thermal expansion coefficient to maintain optical performance under temperature variations, high chemical resistance to withstand harsh environments, and exceptional homogeneity to ensure consistent optical characteristics across the material. These properties collectively contribute to the exceptional performance and reliability of optical glass in diverse optical systems.

5. Versatility in Optical Applications:

Due to its tailored optical properties, optical glass finds extensive use in a myriad of applications, ranging from precision optics in scientific research to medical imaging, telecommunications, astronomy, and consumer electronics. Its versatility and adaptability to various optical requirements make optical glass a cornerstone of innovation and technological advancement in the field of optics.

Characteristics of Optical Glass:

Optical glass possesses a unique set of characteristics that make it indispensable in the field of optics. Let’s delve into the key attributes that define optical glass and elucidate how each contributes to its effectiveness in diverse optical systems:

1.Transparency:

1.Transparency:

- Optical glass is renowned for its exceptional transparency, allowing light to pass through with minimal absorption or scattering. This property is vital for maintaining the fidelity of images transmitted through optical components.

- The high transparency of optical glass ensures that minimal light energy is lost during transmission, resulting in sharp and clear images.

2.Refractive Index:

- The refractive index of optical glass determines how light propagates through the material. Different types of optical glass have varying refractive indices, which impact the bending of light rays as they pass through the glass.

- Precise control over the refractive index of optical glass enables lens designers to manipulate light paths, correct aberrations, and achieve desired optical effects.

3.Dispersion:

- Dispersion refers to the separation of light into its component colors as it passes through a medium. Optical glass exhibits controlled dispersion properties, allowing for the correction of chromatic aberrations in optical systems.

- By carefully selecting optical glass with specific dispersion characteristics, designers can ensure that different wavelengths of light converge at the same focal point, enhancing image quality and color accuracy.

4.Thermal Properties:

- The thermal properties of optical glass are crucial for maintaining optical performance across a range of temperatures. Optical glass is engineered to have low coefficients of thermal expansion, reducing the risk of distortion or damage under thermal stress.

- These thermal properties ensure that optical components retain their shape and optical properties even when subjected to temperature variations, making optical glass suitable for a wide range of operating conditions.

Resistance to Environmental Factors:

- Optical glass is designed to withstand environmental factors such as humidity, temperature fluctuations, and chemical exposure. Its robust nature ensures long-term stability and performance reliability in diverse settings.

- The resistance of optical glass to environmental factors minimizes the need for frequent maintenance or replacements, making it a cost-effective and durable choice for optical systems.

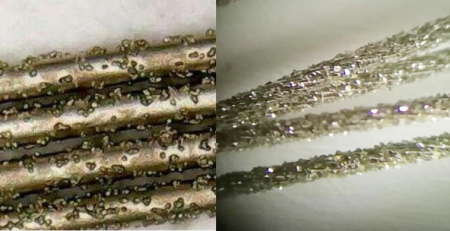

Advantages of Diamond Wire Cutting for Optical Glass:

Diamond Wire Cutting:

- Точность: Diamond wire cutting utilizes a thin wire embedded with diamond particles to make precise cuts in optical glass. The hardness of diamonds allows for intricate and accurate cutting, ensuring minimal deviations from the desired dimensions.

- Эффективность: This method offers high cutting speeds and efficiency, enabling rapid production of intricate shapes and designs in optical glass. The continuous cutting action of the diamond wire results in smooth edges and precise outcomes.

- Минимальные потери материала: Diamond wire cutting produces minimal material wastage due to its thin kerf width. This results in cost savings and maximizes the utilization of the expensive optical glass material.

Лазерная резка:

- Точность: Laser cutting is known for its precision and ability to create complex patterns in optical glass. The focused laser beam allows for fine detailing and intricate cuts.

- Speed: Laser cutting can be a fast process, particularly for thin optical glass materials. It offers quick turnaround times for cutting projects.

- Heat-Affected Zone: One drawback of laser cutting is the potential for a heat-affected zone around the cut area, which can lead to thermal stress and potential damage to the optical properties of the glass.

Traditional Methods:

- Многосторонность: Traditional mechanical cutting methods involve the use of tools like saws or blades to cut optical glass. While versatile, these methods may not offer the same level of precision as diamond wire cutting or laser cutting.

- Cost: Mechanical cutting can be cost-effective for simpler cutting tasks but may result in more material wastage and rougher edges compared to more advanced cutting techniques.

Advantages of Diamond Wire Cutting for Optical Glass:

- Высочайшая точность: Diamond wire cutting provides unmatched precision, making it ideal for intricate optical components and precision parts.

- Эффективность: The efficiency of diamond wire cutting allows for high-volume production with consistent quality and accuracy.

- Чистые срезы: The clean cuts produced by diamond wire cutting minimize the need for additional finishing processes, saving time and resources.

В заключение:

While various cutting methods are available for optical glass, diamond wire cutting stands out as the preferred choice due to its precision, эффективность, and minimal material loss. By leveraging the advantages of diamond wire cutting, manufacturers can achieve superior quality and accuracy in cutting optical glass components, meeting the demands of modern optical applications with excellence.