Повышение устойчивости: Экологически чистые аспекты станков для резки алмазной канатной пилой

В области промышленного оборудования, Стремление к устойчивому развитию стало краеугольным камнем инноваций. Среди этих достижений, тем станок для резки алмазной проволоки stands out as a versatile tool that combines precision cutting with eco-conscious design. В этой записи блога, Мы углубляемся в экологически чистые аспекты наших станков для резки алмазной канатной пилой, подчеркивая их устойчивые особенности, включая интеграцию резервуаров для воды для эффективного использования воды, Продвижение «зеленых» практик, и обеспечение экологически чистого процесса резки.

Water Efficiency and Sustainable Resource Management

Water Efficiency and Sustainable Resource Management

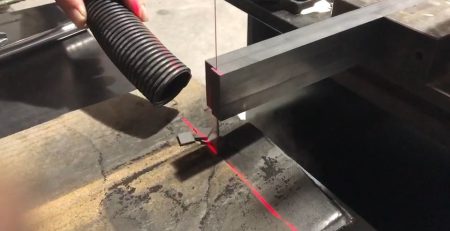

At the heart of our commitment to sustainability is the incorporation of water tanks in our diamond wire saw cutting machines. Water is a crucial element in the cutting process, serving to cool the wire and flush away debris. By equipping our machines with water tanks, we ensure efficient water usage during operation. This feature not only minimizes water wastage but also promotes sustainable resource management, making the most of this essential resource while reducing environmental impact.

Green Practices and Pollution-Free Operation

Our diamond wire saw cutting machines are designed with green practices in mind, aiming to minimize their environmental footprint. The integration of water tanks plays a significant role in this endeavor by enabling a pollution-free cutting process. As water is used to suppress dust and cool the cutting wire, it prevents the release of harmful particles into the air, creating a cleaner and safer working environment. This eco-friendly approach aligns with our commitment to sustainability and underscores our efforts to promote responsible manufacturing practices.

Advantages of Water Tanks in Diamond Wire Saw Cutting Machines

The inclusion of water tanks in our diamond wire saw cutting machines offers a multitude of benefits that contribute to their eco-friendly nature. By effectively cooling the cutting wire, water tanks enhance the machine’s performance and longevity, ensuring optimal cutting results while reducing the risk of overheating. Дополнительно, the use of water as a coolant helps to maintain the integrity of the materials being cut, resulting in cleaner cuts and minimizing material waste. This not only enhances the efficiency of the cutting process but also promotes sustainable practices by maximizing resource utilization.

Promoting Sustainability Through Innovation

As advocates for sustainability, we are continuously exploring innovative solutions to enhance the eco-friendliness of our diamond wire saw cutting machines. By leveraging technology and design advancements, we aim to further reduce energy consumption, optimize water usage, and minimize environmental impact. Through ongoing research and development, we strive to push the boundaries of eco-friendly manufacturing, setting new standards for sustainable industrial equipment.

Commitment to Environmental Stewardship

Our dedication to environmental stewardship extends beyond the design of our diamond wire saw cutting machines. We are committed to fostering a culture of sustainability within our organization, promoting responsible practices at every stage of production. From sourcing materials to manufacturing processes, we prioritize eco-friendly solutions that uphold our commitment to environmental preservation. By integrating water tanks into our machines and embracing sustainable practices, we aim to lead by example in the pursuit of a greener future.

В заключение, the eco-friendly aspects of our diamond wire saw cutting machines underscore our dedication to sustainability and environmental responsibility. Through the integration of water tanks for efficient water usage, promotion of green practices, and commitment to pollution-free operation, we strive to set a new standard for eco-conscious manufacturing. As we continue to innovate and evolve, we remain steadfast in our mission to advance sustainability in the industrial sector and contribute to a cleaner, greener world.