Решение болевых точек отрасли: Преимущества бесконечной алмазной канатной пилы в секторе резки

In today’s rapidly evolving technological landscape, Режущая промышленность играет решающую роль в различных секторах, в том числе строительство, производственный, и горнодобывающей промышленности. Однако, Традиционные методы резки часто сталкиваются с несколькими болевыми точками, Снижение эффективности, точность, и рентабельность. В этом блоге, we will explore the challenges faced in the cutting domain and shed light on the remarkable advantages of the бесконечная алмазная проволочная пила, Революционный режущий инструмент.

1.Отраслевые болевые точки:

1.Отраслевые болевые точки:

1.1 Трудоемкий процесс:

Традиционные методы резки, такие как распиловка, шлифование, and abrasive cutting often require substantial time investments due to their limitations in speed, точность, and material adaptability.

1.2 Inefficiency and Material Loss:

Conventional cutting methods are often associated with significant material wastage due to their inability to minimize kerf width, resulting in increased costs and environmental concerns.

1.3 Limited Cutting Range:

Many cutting tools have limitations when it comes to cutting different materials, especially hard and brittle ones. This hampers productivity and restricts the possibilities for various industries.

1.4 Safety Concerns:

Manual cutting processes, such as using handheld saws or abrasive discs, can pose significant safety risks for operators due to the potential for accidents, injuries, and exposure to harmful dust or fumes.

2.The Advantages of Endless Diamond Wire Saw:

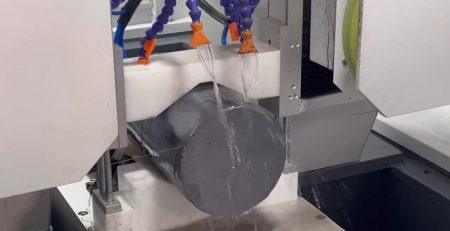

2.1 Повышенная скорость резания:

Тем бесконечная алмазная проволочная пила revolutionizes the cutting industry by significantly increasing cutting speed compared to traditional methods. This is achieved through the use of a thin, continuous wire embedded with diamond beads that efficiently cuts through various materials, в том числе камень, металл, стекло, и композиты.

2.2 Precision and Reduced Kerf Width:

Endless diamond wire saws offer exceptional precision, allowing for intricate cuts with minimized kerf width. This not only optimizes material utilization but also reduces post-cutting processing requirements, saving time and costs.

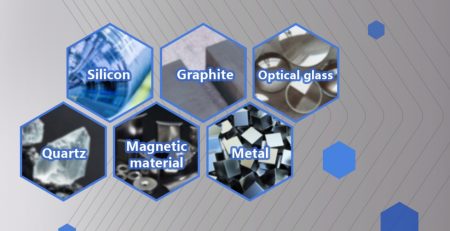

2.3 Versatility and Material Adaptability:

With the ability to cut through a wide range of materials, the endless diamond wire saw eliminates the need for multiple cutting tools. From delicate glass to robust metal alloys, this cutting innovation can adapt to various materials, enhancing productivity and versatility.

2.4 Increased Safety:

Endless diamond wire saws prioritize operator safety. With a controlled cutting process and reduced manual intervention, the risks associated with traditional cutting methods, such as accidents and exposure to hazardous substances, are significantly minimized.

2.5 Экономичность:

By minimizing material wastage, reducing processing time, and streamlining operations, endless diamond wire saws offer tangible cost savings for industries. The efficiency and precision of this cutting tool translate into improved productivity and reduced overheads.

Заключение:

The cutting industry has long grappled with pain points that hinder efficiency, точность, and safety. Однако, the emergence of the endless diamond wire saw has provided a game-changing solution. By addressing the challenges faced by traditional cutting methods, this cutting-edge technology offers enhanced speed, точность, versatility, безопасность, и рентабельность. As industries continue to evolve, the endless diamond wire saw stands as a testament to the transformative power of innovative solutions in overcoming industry pain points.