Типы станков для резки алмазной канатной пилой

Станки для резки алмазной канатной пилой являются передовыми инструментами, используемыми в различных отраслях промышленности для точных операций резки. От добычи полезных ископаемых до строительства, Эти машины играют решающую роль в придании формы и резке твердых материалов, таких как камень, бетон, и металлов. В этой статье рассматриваются различные типы станков для резки алмазной канатной пилой и их применение в современных отраслях промышленности.

Типы станков для резки алмазной канатной пилой:

Типы станков для резки алмазной канатной пилой:

Канатные пилы непрерывного действия:

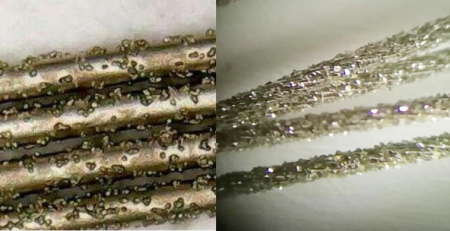

Описание: Канатные пилы непрерывного действия состоят из непрерывной петли алмазной проволоки, которая проходит по набору шкивов.

Приложений: Идеально подходит для резки больших каменных блоков, такие как мрамор и гранит, в плиты или плитку с высокой точностью.

Многоканатные пилы:

Описание: Многоканатные пилы используют несколько параллельных алмазных проволок для одновременной резки материалов.

Приложений: Обычно используется в полупроводниковой промышленности для резки кремниевых слитков и пластин с минимальными потерями материала.

Стационарные канатные пилы:

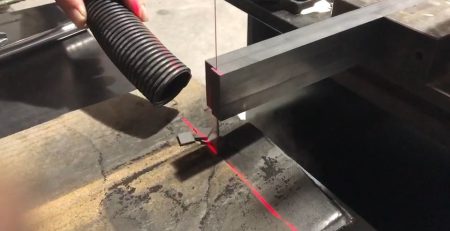

Описание: Стационарные канатные пилы – это стационарные станки, в которых разрезаемый материал перемещается относительно алмазной проволоки.

Приложений: Подходит для резки толстых плит из твердых материалов, таких как бетон и железобетон.

Портативные канатные пилы:

Описание: Портативные канатные пилы компактны и легки, Что обеспечивает легкую транспортировку к рабочим площадкам.

Приложений: Идеально подходит для резки на строительной площадке в строительных проектах, где важна мобильность.

Применение станков для резки алмазной канатной пилой:

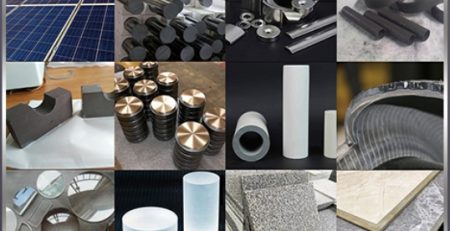

- В горнодобывающей промышленности: Станки для резки алмазной канатной пилой используются для точной добычи минеральных отложений и резки крупных блоков камня в карьерах.

- В строительной отрасли: Эти машины играют жизненно важную роль в резке бетона, железобетон, и каменная кладка для различных строительных проектов.

- В полупроводниковой промышленности: Станки для резки алмазной канатной пилой необходимы для нарезки силиконовых слитков на тонкие пластины для производства полупроводников.

Преимущества станков для резки алмазной канатной пилой:

- Прецизионная резка: Станки с алмазной канатной пилой обеспечивают высокую точность резки с минимальными потерями материала.

- Многосторонность: Эти станки могут резать широкий спектр материалов, в том числе и твердые камни, Металлов, и композиты.

- Эффективность: Станки для резки алмазной канатной пилой эффективны и позволяют значительно сократить время резки по сравнению с традиционными методами.

- Безопасность: При надлежащем обучении и обслуживании, Станки для резки алмазной канатной пилой безопасны в эксплуатации, обеспечение безопасности работников на рабочем месте.

Заключение:

Станки для резки алмазной канатной пилой произвели революцию в способах резки и придания формы твердым материалам в различных отраслях промышленности. С их точностью, многосторонность, и эффективность, Эти машины стали незаменимыми инструментами для современных производственных и строительных процессов. Понимание различных типов и областей применения станков для резки алмазной канатной пилой имеет важное значение для использования их полного потенциала в промышленных операциях.