The Difference between Diamond Wire Saw and Diamond Loop Wire

Introduction:

When it comes to precision cutting in various industries, diamond wire saws and diamond loop wires(Also known as:endless diamond wire saw) play a vital role. While both are equipped with diamond particles for cutting, they have distinct differences in terms of materials, structures, cutting methods, costs, and determining the appropriate choice for specific applications. In this blog post, we will explore these differences and provide insights on how to choose the right product for your cutting needs.

1.Different structures:

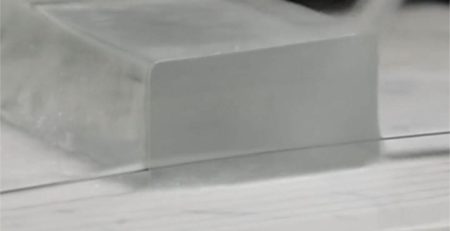

- A diamond wire saw typically consists of a thin wire made of stainless steel or other high-strength materials, with diamond particles embedded in a matrix or coating along the length of the wire. The diamond particles are securely bonded to the wire, allowing for efficient cutting of various materials.

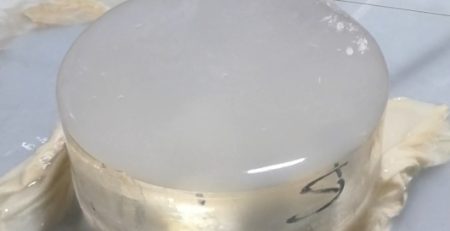

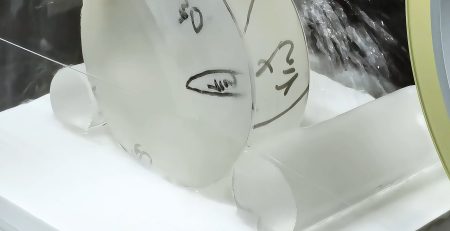

On the other hand, a diamond loop wire, as the name suggests, is formed into a closed-loop structure. The wire itself is often made of high-quality steel or other durable materials, while the diamond particles are embedded and securely held within the looped wire structure. This closed-loop design ensures stability and precise cutting during the cropping process of silicon wafers.

On the other hand, a diamond loop wire, as the name suggests, is formed into a closed-loop structure. The wire itself is often made of high-quality steel or other durable materials, while the diamond particles are embedded and securely held within the looped wire structure. This closed-loop design ensures stability and precise cutting during the cropping process of silicon wafers.

2. Different cutting methods:

2. Different cutting methods:

- Diamond wire saws utilize a continuous cutting method. They consist of a thin wire, typically made of stainless steel or other high-strength materials, embedded with diamond particles. These diamond particles are driven by electrical or mechanical power to create a continuous cutting motion. This design is suitable for applications that require long-distance and straight-line cutting. Diamond wire saws are widely used in industries such as construction, mining, and semiconductor manufacturing.

- In contrast, diamond loop wires employ a closed-loop cutting method. The diamond particles are embedded within the closed loop structure, creating a circular cutting tool. This closed-loop design allows diamond loop wires to achieve high precision and quality cutting in specific applications such as cropping silicon wafers. The closed-loop nature ensures stability and accuracy during cutting, making it ideal for the precise requirements of the semiconductor industry.

3. Different application materials:

- The diamond wire saw is a versatile cutting tool that is suitable for various materials. It can be used to cut materials such as stone, metal, wood, concrete, and more. The diamond particles are embedded in a thin wire, giving it excellent cutting performance and durability.

- Diamond loop wire is mainly used for cutting materials such as silicon wafers, optical glass, sapphire, ceramic targets, and batteries. It is primarily designed for industrial material cutting, with high precision and quality requirements. The diamond loop wire, with its unique closed-loop structure and embedded diamond particles, enables high-precision cutting of silicon wafers, ensuring smooth and accurate cut surfaces.

4.Costs are different:

- Diamond wire saw has relatively lower cost. It consists of a thin wire with embedded diamond particles, and the wire is typically made of stainless steel or other high-strength materials. Although the quality and quantity of diamond particles can affect the cost, the manufacturing and material costs of diamond wire saw are generally lower compared to diamond loop wire.

- Diamond loop wire, on the other hand, has relatively higher cost. It is manufactured by embedding diamond particles in a closed-loop structure. The production of this closed-loop structure and the embedding of diamond particles require higher process and technical requirements, leading to higher manufacturing cost.

- Additionally, diamond loop wire usually has a longer lifespan compared to diamond wire saw. Due to the diamond particles being securely fixed in the closed-loop structure, diamond loop wire exhibits higher wear resistance and longevity, allowing for longer cutting operations. This also means that the cost of diamond loop wire can be spread over a longer period, potentially providing better cost-effectiveness in the long run.

How to choose the right product

Choosing the right product requires considering several factors:

- Firstly, it is important to clarify your needs. Determine the type of material to be cut, the required cutting precision, and budget limitations. Different products are suitable for different materials and requirements, so clarifying your needs can help narrow down the options.

- Secondly, consider the quality and performance of the product. Gather information about the material quality, manufacturing process, and user reviews to assess the product’s quality and performance. High-quality products typically offer better cutting results and longer lifespan.

- Additionally, consider the product’s reliability and after-sales service. Choosing reputable brands and suppliers ensures the reliability of the product and quality of after-sales service. These factors are crucial for long-term use and maintenance of the product.

- Price and cost-effectiveness should also be taken into account. Select products that fit within your budget while offering good performance. Comparing prices and performance across different brands and models can help make a more informed decision.

- Moreover, it can be helpful to consider reviews and opinions from other users. Reading product reviews, participating in online forums, or consulting professionals can provide additional insights and recommendations based on other users’ experiences.

In conclusion

If you have any further questions, please don’t hesitate to reach out to us. We have our own team of engineers and factories, and we offer ODM services. We believe that we can provide you with better solutions.