The Ultimate Guide to Understanding Graphite

Introduction:

Graphite, a crystalline form of carbon, holds a pivotal place in various industries due to its unique properties and versatile applications. In this comprehensive guide, we delve into the characteristics of graphite, its diverse uses across industries, and the intricate process of machining graphite, including the cutting of graphite using diamond wire saw technology.

1. Characteristics of Graphite:

1. Characteristics of Graphite:

Graphite is characterized by its exceptional properties that set it apart from other materials:

- Structure: Graphite features a layered structure with hexagonally arranged carbon atoms, providing it with lubricious and slippery qualities.

- Conductivity: It exhibits high thermal and electrical conductivity, making it a valuable material in applications requiring heat and electricity conduction.

- Lubrication: Graphite’s layered structure allows for easy slippage between layers, making it an excellent dry lubricant in various mechanical applications.

- Chemical Inertness: Graphite is chemically inert and resistant to most acids, bases, and solvents, contributing to its durability and longevity in harsh environments.

2. Uses of Graphite:

Graphite finds extensive applications across diverse industries due to its unique properties:

- Refractories: Graphite is used in refractory materials for its high thermal stability and resistance to heat, making it ideal for lining furnaces and crucibles.

- Electrodes: It serves as electrodes in the manufacturing of steel, aluminum, and other metals due to its excellent conductivity and high temperature resistance.

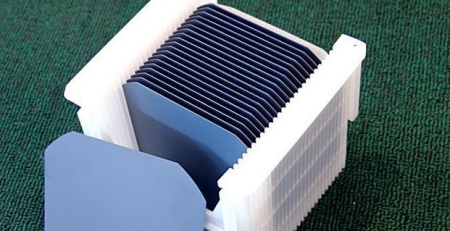

- Batteries: Graphite is a key component in lithium-ion batteries, providing stability and conductivity in energy storage systems.

- Automotive Industry: It is used in various automotive components, such as gaskets and brake linings, for its self-lubricating and thermal management properties.

3. Processing Graphite:

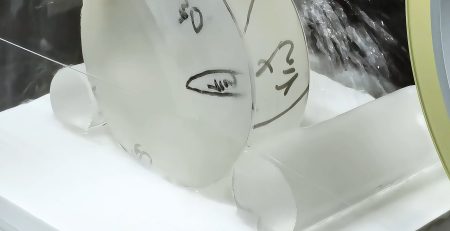

Graphite processing involves intricate techniques to shape and refine the material for specific applications. One crucial method is cutting graphite with diamond wire saw technology:

- Diamond Wire Saw Cutting: Diamond wire saw machines equipped with high-quality diamond-coated wires are utilized to cut graphite blocks with precision and efficiency. The hardness and abrasion resistance of the diamond wire ensure clean and accurate cuts without compromising the integrity of the graphite material.

Advantages: Diamond wire saw cutting provides smooth edges, minimal material wastage, and high cutting speeds, making it a preferred method for processing graphite in industries requiring precise dimensions and superior surface finishes.

Advantages: Diamond wire saw cutting provides smooth edges, minimal material wastage, and high cutting speeds, making it a preferred method for processing graphite in industries requiring precise dimensions and superior surface finishes.

In conclusion:

Graphite’s remarkable properties, diverse applications, and the advanced machining techniques involved in its processing, including diamond wire saw cutting, underscore its significance as a valuable material in modern industrial processes. Understanding the intricacies of graphite opens doors to innovative solutions across a wide range of industries, driving progress and efficiency in manufacturing and technology sectors.