What are the advantages of diamond wire cutting compared with the traditional inner circle cutting machine?

Internal machine cutting and diamond wire cutting each have their own advantages and application scenarios, but with the development of technology, more and more industries are beginning to favor endless diamond wire loop cutting.

Internal machine cutting is an automatic metal cutting equipment, mainly used for small area, high-precision cutting, and can be cut a variety of different shapes. This cutting method is suitable for precision machining, special-shaped cutting and other scenes, and has the advantages of high precision and high efficiency.Of course, there are disadvantages, the level of the operator is high, the edge is more dangerous, loud noise;

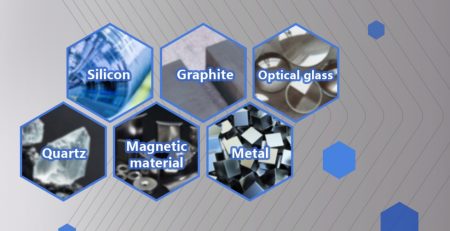

Endless diamond wire loop cutting is a kind of cutting equipment using diamond wire, mainly used for large area cutting, such as optical glass, silicon, graphite, ceramics, gems and other hard materials cutting. This cutting method has the advantages of fast cutting speed, good incision quality, less material loss, wide application range, but compared with the internal machine cutting, the accuracy of the equipment will be higher technical requirements.

Endless diamond wire loop cutting is a kind of cutting equipment using diamond wire, mainly used for large area cutting, such as optical glass, silicon, graphite, ceramics, gems and other hard materials cutting. This cutting method has the advantages of fast cutting speed, good incision quality, less material loss, wide application range, but compared with the internal machine cutting, the accuracy of the equipment will be higher technical requirements.

Therefore, if you need high precision, small size cutting, you can choose the internal machine cutting; If you need to cut large areas of hard and brittle materials, the pursuit of cutting quality can choose endless diamond wire saw cutting.