What are the advantages of diamond Wire loop cutting?

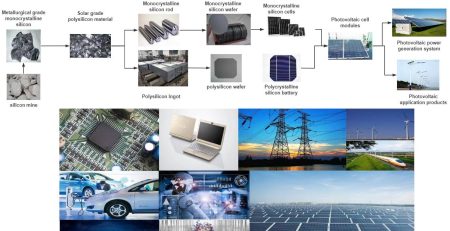

Diamond-Wire-loop cutting technology is an advanced cutting technology to replace the traditional free mortar cutting, which is widely used in the field of silicon wafer cutting in photovoltaic and semiconductor industries.

Its development process is as follows:

The first stage: originated in Japan, mainly cut with free abrasive mortar, including abrades such as zirconium corundum and silicon carbide.The second stage: Japan Asahi Diamond Industry Co., LTD. (hereinafter referred to as “Asahi Diamond”) and other companies began to produce 17.5mm diameter of fine grained diamond lines.The third stage: Asahi Diamond, Japan Nakamura Superhard Co., LTD. (hereinafter referred to as “Nakamura Superhard”) and other companies began to produce ultra-fine grained diamond lines with a diameter of 14.5mm.The fourth stage: diamond wire manufacturing enterprises represented by China have gradually risen in the market, and diamond wire cutting technology has been widely used.

The advantages of diamond Wire loop cutting mainly include——Cutting speed, high efficiency, high productivity.

The advantages of diamond Wire loop cutting mainly include——Cutting speed, high efficiency, high productivity.

Higher precision and lower damage layer, material loss and burn when cutting thin sheets, which is conducive to cutting thinner silicon wafers or other high-value raw materials.

Quality control, low cost per piece.

The use of water-based grinding fluid is conducive to improving the working environment and simplifying the post-processing procedures such as cleaning, which is simple and environmentally friendly.

Therefore, diamond loop cutting has become the mainstream cutting process for crystalline silicon slicing in the photovoltaic industry. Since 2015, Zhengzhou Ensolltools Technology Co., Ltd. began to deeply cultivate the field of diamond wire saw cutting, product competitiveness continues to improve, and market share increases year by year.

In terms of diamond loop, the company continues to lead the industry in fining, has broken through the 0.3mm diamond loop technical barriers, and actively develop reserves and trial production of finer diameter diamond loop, With the diamond loop cutting equipment developed by us, thinner wire diameter helps to reduce the cutting loss of raw materials, especially rare and valuable materials, while improving cutting accuracy and efficiency. Reduce cutting energy consumption.