What is the effect of diamond wire saw cutting optical glass?

Diamond wire loop saw cutting is an advanced glass cutting method, especially suitable for cutting hard glass materials, such as optical glass. Its advantages include high precision, high speed, good incision quality, etc.

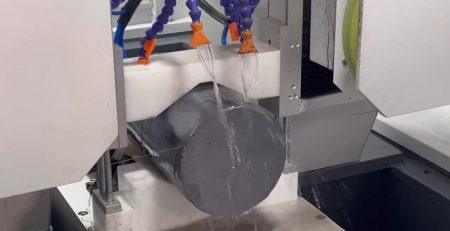

When cutting optical glass with diamond wire loop saw, special cutting equipment and materials are usually required. These devices include diamond wire loop saw, cutting wheels, power supplies and control systems. During the cutting process, the diamond wire loop saw is in contact with the glass surface while rotating at high speed, and the glass is cut through a precise control system.

Advantages of diamond wire loop saw cutting optical glass include:

Advantages of diamond wire loop saw cutting optical glass include:

High precision: Diamond wire loop saw cutting can achieve accurate cutting of glass, with high precision and tolerance control.

High speed: Due to the high hardness of diamond wire, you can quickly cut glass and improve production efficiency.

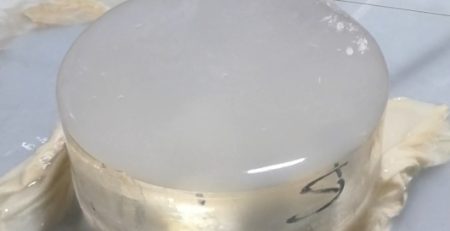

Good cut quality: The cut of diamond wire loop saw cutting is smooth and vertical, reducing the possibility of damage to the glass surface and inside.

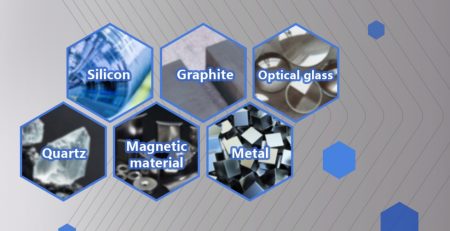

Wide range of application: diamond wire loop saw cutting can be applied to various shapes and sizes of glass cutting, high flexibility.

It should be noted that for different types and hardness of glass materials, it is necessary to select the appropriate diamond wire loop and cutting conditions to ensure cutting quality and efficiency.

In short, diamond wire loop saw cutting is an effective optical glass cutting method, with high accuracy and production efficiency, suitable for cutting a variety of hard and brittle materials.