Why is diamond wire loop saw cutting more and more in the photovoltaic industry?

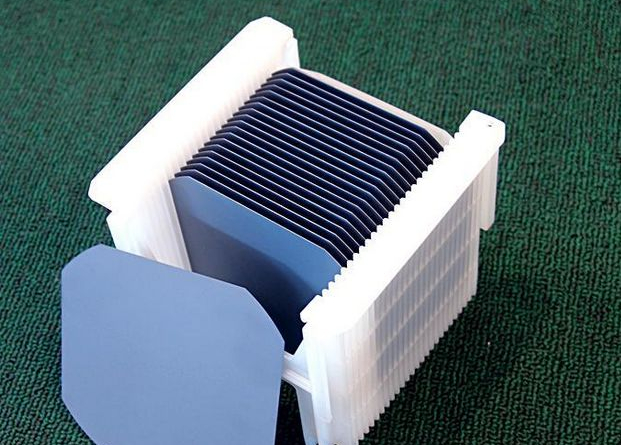

With the continuous development of the photovoltaic industry, the demand for silicon wafers is increasing, and the quality and cutting efficiency of silicon wafers are also put forward higher requirements. As an efficient cutting tool, diamond wire loop has the advantages of fast cutting speed, high precision and low cost, so it has been widely used in the photovoltaic industry.

The photovoltaic industry uses endless diamond wire loop cutting mainly for the following reasons:

Cutting performance: diamond wire loop cutting technology has the advantages of high output rate, fast cutting speed and small environmental pollution. Compared with the traditional mortar cutting technology, diamond wire cutting can improve the cutting efficiency and yield of silicon wafers, while reducing environmental pollution.

Cutting performance: diamond wire loop cutting technology has the advantages of high output rate, fast cutting speed and small environmental pollution. Compared with the traditional mortar cutting technology, diamond wire cutting can improve the cutting efficiency and yield of silicon wafers, while reducing environmental pollution.

Cost consideration: diamond wire loop cutting technology can improve the utilization of raw materials, reduce the loss in the cutting process, thereby reducing production costs.

Market demand: With the rapid development of the photovoltaic industry, the demand for silicon wafers is increasing. Endless diamond wire cutting technology can meet the market demand for efficient and high-quality silicon wafers.

In summary, the photovoltaic industry uses diamond wire loop cutting technology for cutting performance, cost considerations and market demand.